TM 5-3805-281-24-2

Camshaft and Timing Gear Train

INSTALL CAMSHAFT

IMPORTANT: Set engine at TDC of No. 1 piston's

compression stroke before installing

camshaft so timing marks on camshaft

and crankshaft gears will be aligned.

1. If camshaft followers were removed with engine on a

rollover stand, reinstall followers but do not obstruct

camshaft bore. Roll engine to an angle where followers

fall away from camshaft bores.

NOTE: If D15001NU Magnetic Holding Tool Set is used,

hold camshaft followers away from camshaft bore

until camshaft is installed.

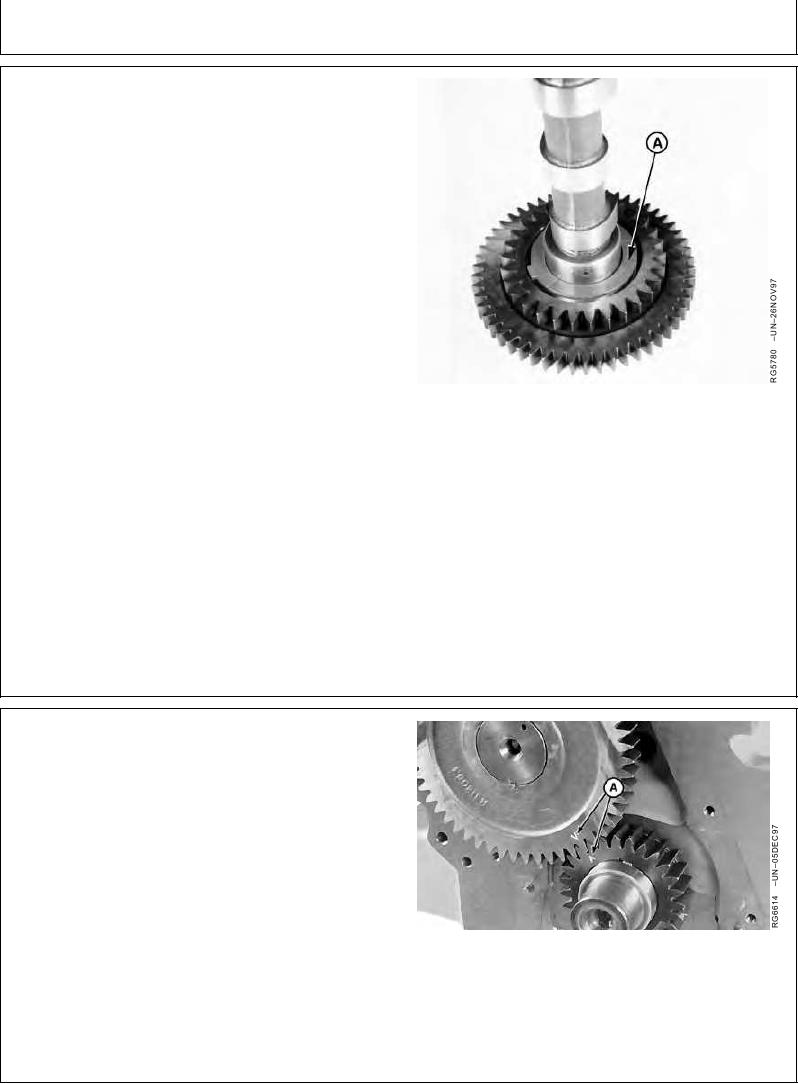

2. Lubricate thrust washer (A) with TY6333 or TY6347

Camshaft Thrust Washer

High Temperature Grease and install on camshaft

behind inner gear.

3. Lubricate camshaft lobes with TY6333 or TY6347 High

Temperature Grease and bearing journals with clean

engine oil.

4. Carefully install camshaft in cylinder block so that

camshaft lobes do not drag in bores. Rotate camshaft

during installation to avoid obstruction in any bore.

RG,RG34710,1210

1923OCT971/2

5. With No. 1 piston on "TDC" compression, align timing

marks (A) on camshaft and crankshaft gears. Check

injection pump timing. (See Group 35.)

Timing Marks--Camshaft and Crankshaft Gears

RG,RG34710,1210

1923OCT972/2