TM 5-3805-281-24-2

Frames

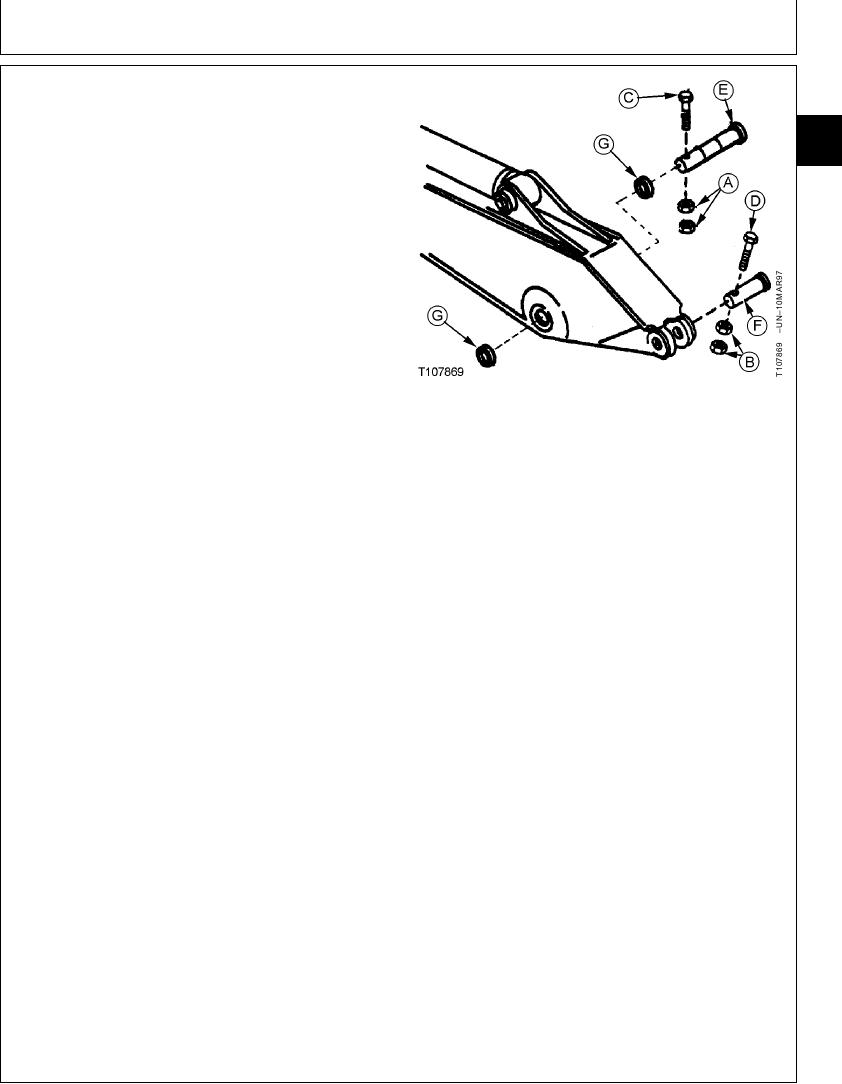

14. Install washers (G) equally on each side of arm to get

minimal amount of clearance at boom-to-arm joint.

33

3340

NOTE: There must be some clearance between boom

11

and arm.

15. Before installing pins (E and F), align pin bores so as

not to damage dust seal when pins are installed.

16. Tighten M20 nuts (A and B) against each other, not

the retainer. Cap screws (C) must be free to turn in

hole.

Boom-to-Arm Pin M20 Cap Screw Nut--Specification

Torque ..................................................... 540 Nm (400 lb-ft) tighten nuts

against each other, not the

retainer

A--M20 Nut (2 used)

Arm-to-Arm Cylinder Pin M20 Cap Screw Nut--Specification

B--M20 Nut (2 used)

C--M20 Cap Screw

Torque ..................................................... 540 Nm (400 lb-ft) tighten nuts

D--M20 Cap Screw

against each other, not the

E--Arm-to-Boom Pin

retainer

F--Arm-to-Arm Cylinder Pin

G--Washer (As Required)

17. For bucket cylinder, install washers equally on each

side of cylinder head and rod end to get minimal

amount of clearance in joints.

NOTE: There must be some clearance in joints.

18. Tighten M20 nuts against each other, not the retainer.

Cap screws (C) must be free to turn in hole

Bucket Cylinder Head End-to-Arm Pin M20 Cap Screw

Nut--Specification

Torque ..................................................... 540 Nm (400 lb-ft) tighten nuts

against each other, not the

retainer

Bucket Cylinder Rod End-to-Link M20 Cap Screw Nut--Specification

Torque ..................................................... 540 Nm (400 lb-ft) tighten nuts

against each other, not the

retainer

19. Apply grease to all pivot joints. (See Track Adjuster,

Working Tool Pivot, Swing Bearing, and Swing

Bearing Gear Grease in Fuels and Lubricants, Group

0004.)

CED,OUOE020,47 1913APR994/4

19-29