TM 5-3805-281-24-2

Hydraulic Impact Breaker

33

BREAKER INLET PRESSURE CALIBRATION

63

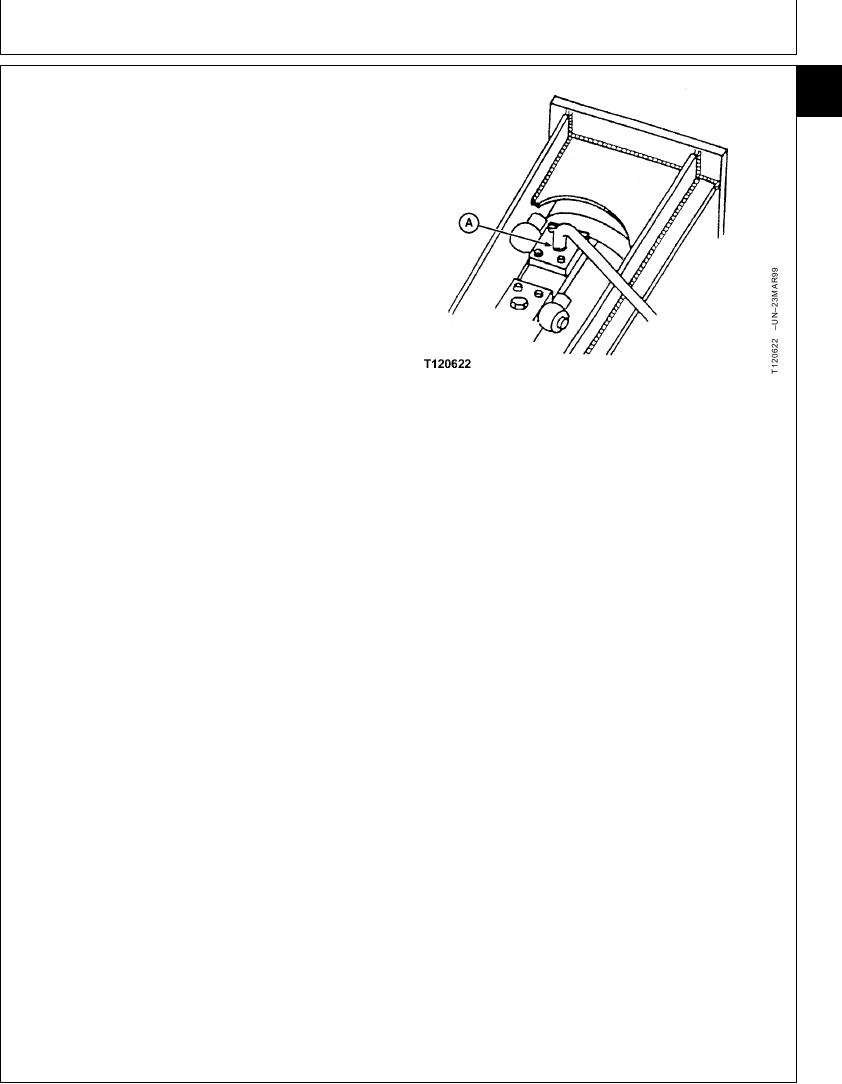

1. Remove 1/4 in. gas plug (A) from high-pressure

connection (A), using 19 mm (.7480") Allen wrench.

Install flow meter in place of breaker. Connect H.P.

breaker line to INLET of flow meter, and L.P. hammer

line to outlet of flow meter. Set restrictor valve to full

open position.

2. Start carrier at low idle and check for line leaks.

Engage breaker control at low idle to bleed air from

flow meter as follows:

a. Operate hydraulic circuit by starting and stopping

circuit a few times.

b. Press electrical control switch and verify that control

valve is working by observing hydraulic flow, which

is shown as a slight movement in hydraulic popes.

c. Let oil run in system for 5-10 minutes, then switch

engine off.

d. Breaker will self-bleed out any trapped air. Run at

half-throttle for 1-2 minutes after hook-up.

3. Have an assistant in the carrier cab. Engage and hold

hammer control. SLOWLY bring carrier RPM up to high

idle and ensure there are no leaks in flow meter

connections. Close flow meter restrictor valve until flow

and pressure on flow meter are in range of the

hammer specifications. Run carrier with circuit engaged

until temperature of hydraulic oil is stabilized.

OIL FLOW CALIBRATION/REGULATION

With oil temperature stabilized and within breaker

specifications, set-up can be started. Adjust flow meter

restrictor to operating pressure of breaker. Observe and

record flow reading on Breaker Delivery Report. If

pressure reading obtained is WITHIN specified range,

proceed to High Back Pressure Level section.

Continued on next page

CED,OUOE039,5

1920MAR992/9

20-59