TM 5-3805-281-24-2

Hydraulic Impact Breaker

33

10. Using some oil, verify that there are no nitrogen leaks

62

from inflating screw or on sides.

11. Turn accumulator upside down and fill holes with oil

to check that diaphragm has no defects. If no bubbles

appear, accumulator is correctly charged and ready to

be fitted to breaker.

CED,OUOE039,4

1920MAR997/7

HYDRAULIC IMPACT BREAKER SET-UP AND

OIL PRESSURE REGULATION

NOTE: All of the following calibration operations must be

carried out when the oil is warm, and the carrier is

at operating temperature.

MATERIALS NEEDED

Tools to properly set up the carrier/breaker combination:

1. Flow meter with adequate range for anticipated flows

and pressures.

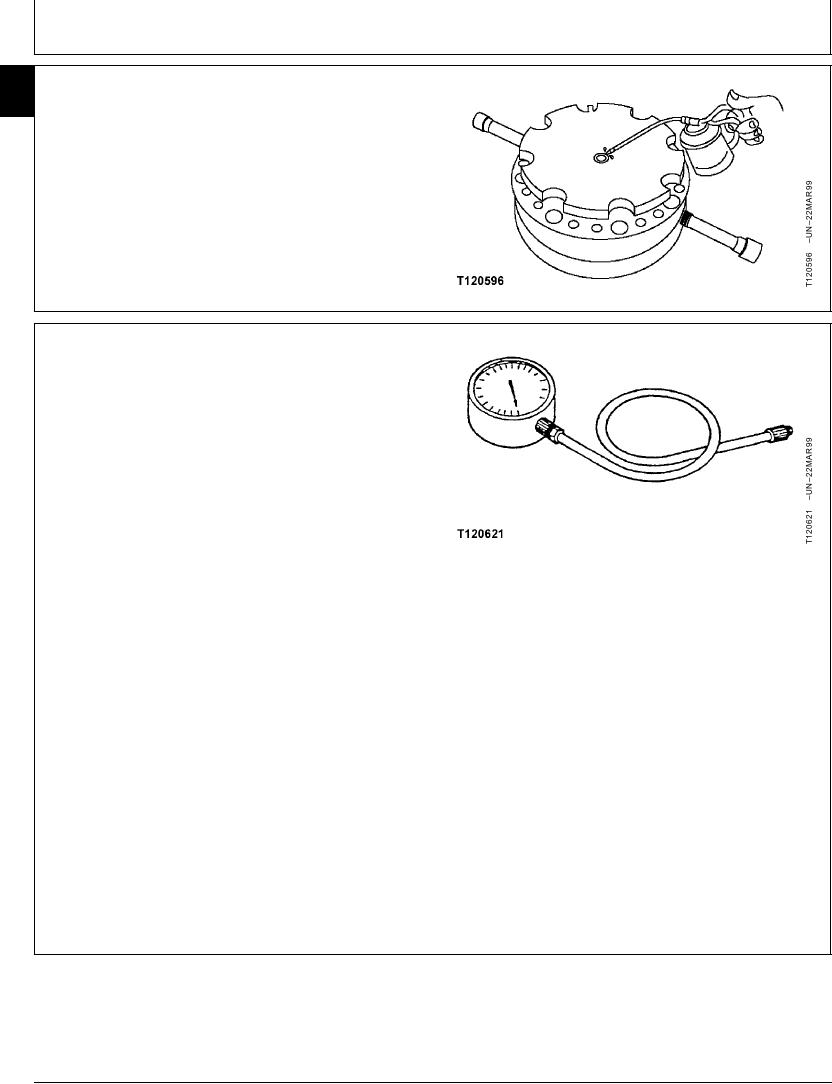

2. Pressure Gauges:

0-3500 or 05000 psi Glycerine-filled Manometer, with

snubber and 1/4 in. NPT male end

0-5000 psi Glycerine-filled Manometer, with snubber

and 1/4 in. NPT male end

Two 1/4 in. BPT to 1/4 in. NPT female adapters

Optional: Two 15 in. hoses to allow gauges to be

held off to the side for confirmation of readings while

breaker is running.

Continued on next page

CED,OUOE039,5

1920MAR991/9