TM 5-3805-281-24-2

Mechanical Drive Elements

43

4350

28

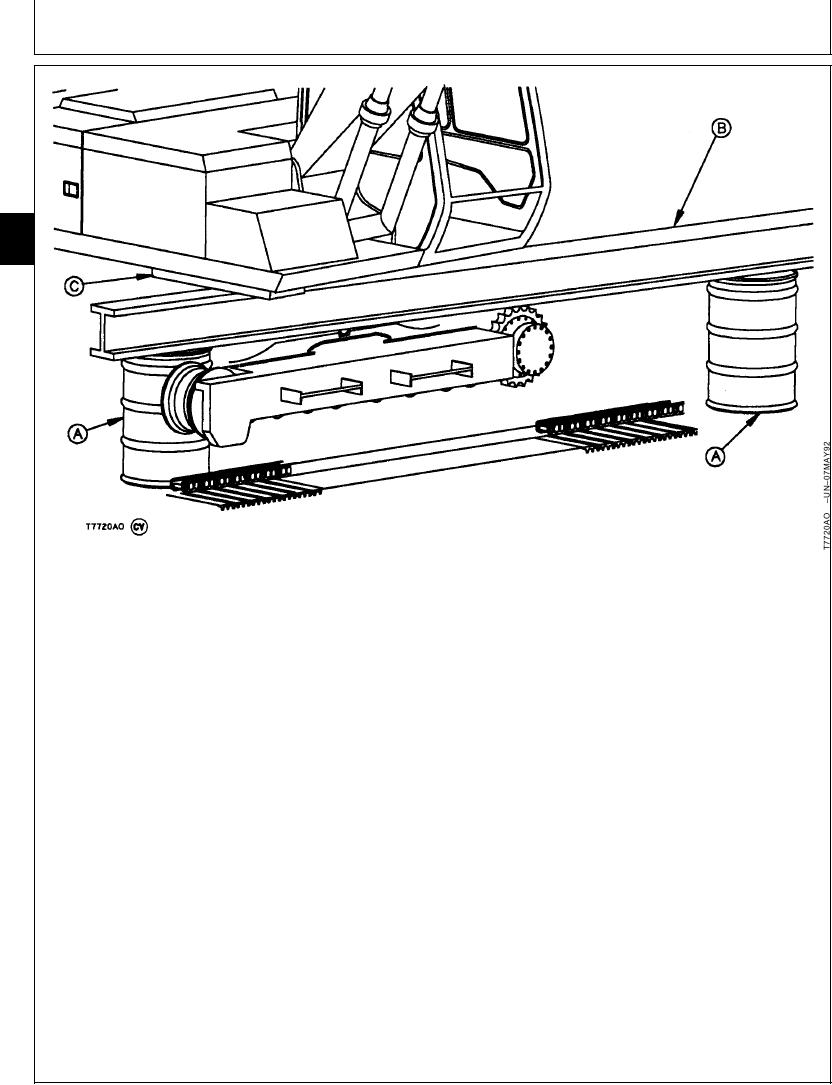

A--DFT1089 Barrel

C--Hardwood Block (As

Support (2 used)

Required)

B--3.7 m (12 ft) Length of

W8 x 35 lb Wide Flange

Beam

16. Tighten any of the swing bearing-to-upperstructure

11. Raise machine just enough to remove hardwood

cap screws that could not be tightened.

blocks (C), wide flange beam (B), and barrel

supports (A).

Swing Bearing-to-Upperstructure Cap Screw--Specification

12. Lower machine so lower track rollers and front

Torque................................................................. 1230 Nm (900 lb-ft)

idler are on track chain.

17. Install track chains. (See procedure in Group

13. Remove bridge planks and barrel supports from

0130).

other side.

18. Adjust track sag. (See procedure in Group 0130.)

14. Turn upperstructure to other side and raise

machine just enough to remove hardwood blocks

between roller and track chain.

15. Lower machine so lower track rollers and front

idler are on track chain.

CED,OUOE027,237

1915MAY984/4

21-27