TM 5-3805-281-24-2

Mechanical Drive Elements

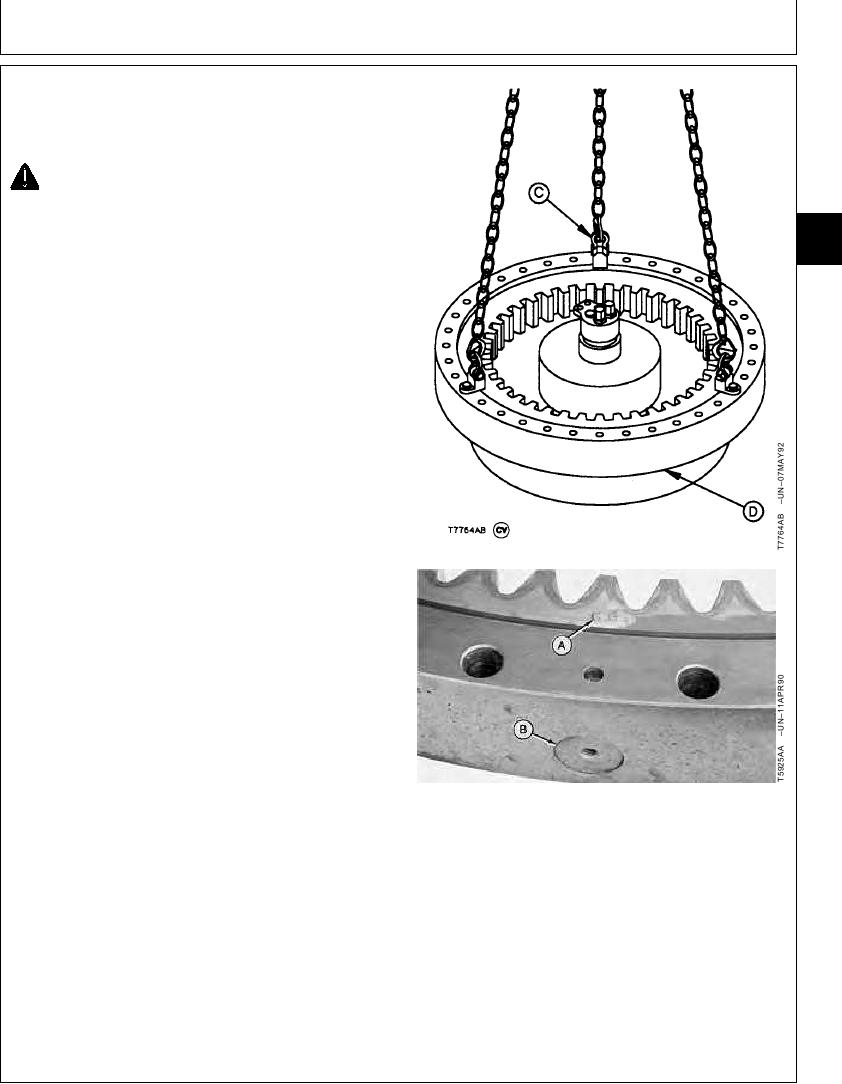

REMOVE AND INSTALL SWING BEARING

1. Remove upperstructure. (See procedure in this group.)

CAUTION: The approximate weight of swing

bearing is 500 kg (1102 lb).

43

Swing Bearing--Specification

4350

29

Weight.......................................................... 500 kg (1102 lb) approximate

2. Connect swing bearing to hoist using lifting brackets

(C) such as JT01748 Lifting Brackets.

3. Remove cap screws (D). Remove bearing.

4. Replace upper and lower seals, steel balls, and

spacers as necessary. (See procedures in this group.)

5. Clean mating surfaces of swing bearing,

upperstructure, and undercarriage using cure primer.

6. Apply plastic gasket to mating surfaces of swing

bearing, upperstructure, and undercarriage.

IMPORTANT: The tooth marked with the letter "G" or

"S", or equivalent is the starting and

stopping point for the hardening

process. The tooth and bearing loading

plug must be installed on right side of

machine so use of that part of swing

bearing is minimized.

7. Install swing bearing on undercarriage so tooth (A)

marked "G" or "S", or equivalent and bearing loading

plug (B) is to right side of machine.

8. Install cap screws (D) and tighten.

Swing Bearing-to-Undercarriage Cap Screw--Specification

A--Tooth

Torque ....................................................................... 1230 Nm (900 lb-ft)

B--Loading Plug

C--Lifting Bracket (3 used)

9. Apply multi-purpose grease to swing bearing teeth and

D--Cap Screw (36 used)

pinion shaft. (See Track Adjuster, Working Tool Pivot,

Swing Bearing, and Swing Bearing Gear Grease in

Group 0004.)

CED,OUOE027,236

1915MAY981/1