TM 5-3805-281-24-2

Mechanical Drive Elements

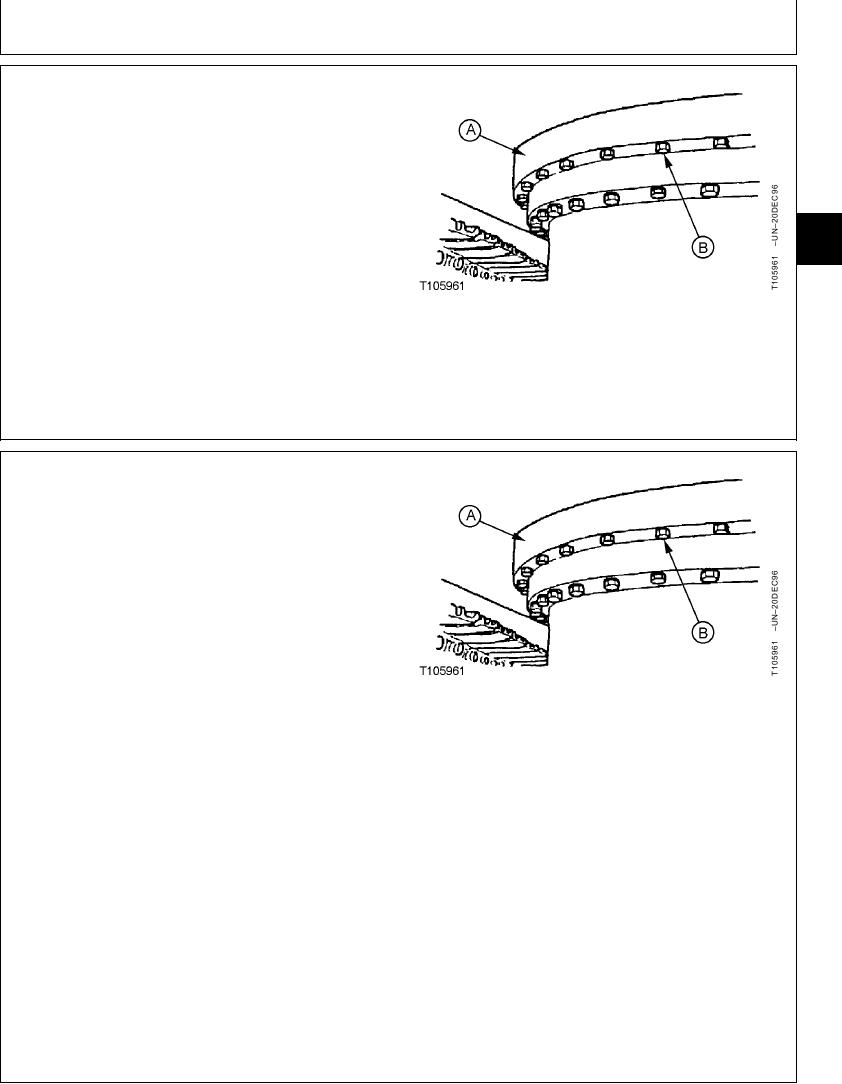

17. Remove cap screws (B) from swing bearing (A).

18. Replace parts as necessary.

19. Slowly lower undercarriage onto track chain.

20. Lift sprocket end of undercarriage so sprocket clears

track chain.

43

4350

21. Pull undercarriage out from under upperstructure.

25

22. Remove swing bearing. (See procedure in this group.)

A--Swing Bearing

B--Cap Screw (36 used)

CED,OUOE027,235

1915MAY987/7

INSTALL UPPERSTRUCTURE

1. Push undercarriage under upperstructure.

2. Install guide pins to help align holes in swing bearing

(A) with holes in main frame. (See Section 99 for

instructions to make tool.)

3. Raise undercarriage into position using two 18-t

(20-ton) service jacks. It may be necessary to turn

swing bearing inner race to align teeth with teeth on

swing motor pinion shaft.

A--Swing Bearing

NOTE: If all cap screws are not accessible, tighten them

B--Cap Screw (36 used)

after the machine has been lowered and supports

have been removed.

4. Install cap screws (B) in swing bearing (A) and tighten

cap screws.

Swing Bearing-to-Upperstructure Cap Screw--Specification

Torque ....................................................................... 1230 Nm (900 lb-ft)

Continued on next page

CED,OUOE027,237

1915MAY981/4