TM 5-3805-294-23-1

0033

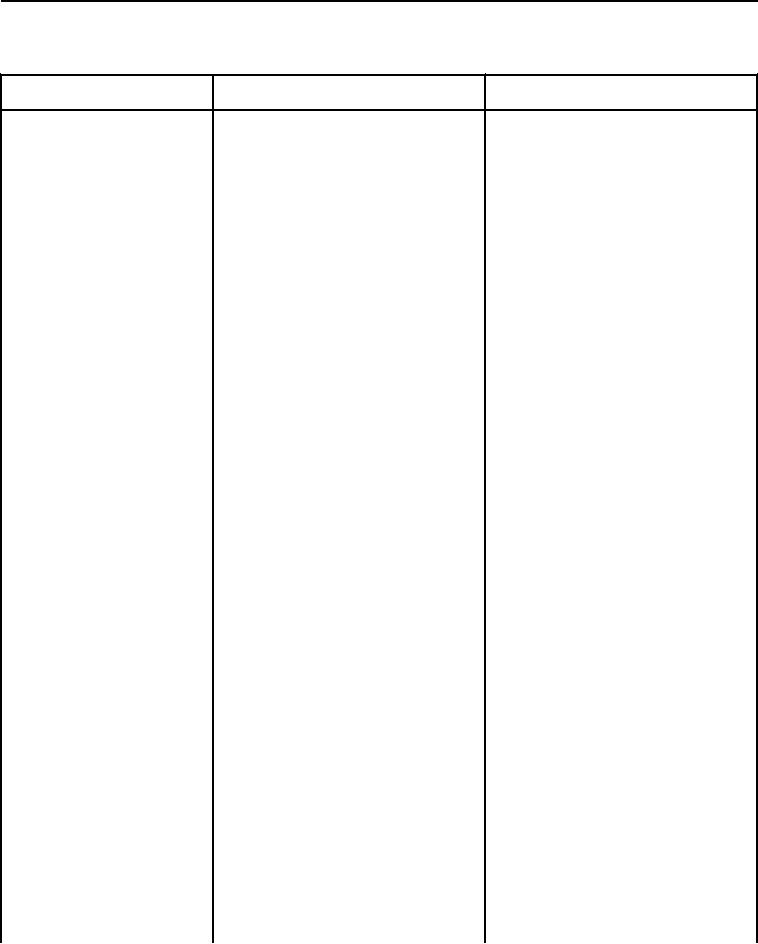

Table 1. DTC 110.04 - Coolant Temperature Signal Out of Range Low - Continued.

Test or Inspection

Corrective Action

Malfunction

Visually inspect engine wiring

1.

If damaged, replace engine

3.

Engine Wiring

harness for pinched or melted

wiring harness. (Volume 4,

Harness Damaged

wires between engine wiring

Between Engine

WP 0510) Restore machine to

harness connector T04

Wiring Harness

original condition and perform

Connectors J03 and

(Volume 5, WP 0800, Figure

Harness Diagnostic Mode

T04.

69) and engine wiring harness

Test. (Volume 3, WP 0345)

connector J03. (Volume 5,

2.

If not damaged, proceed to

WP 0800, Figure 48)

Malfunction 4.

Measure resistance (Volume

1.

If less than 1 kohms, replace

4.

Short Circuit

engine coolant temperature

Between Engine

3, WP 0369) between pin A or

Coolant

pin B on engine coolant

sensor. (Volume 3, WP 0412)

Temperature

temperature sensor to a known

Restore machine to original

Sensor Pins A or B

good ground. (Volume 5,

condition and perform Harness

and Ground.

Diagnostic Mode Test.

WP 0800, Figure 69) Note

(Volume 3, WP 0345)

reading.

2.

If greater than 1 kohms,

proceed to Malfunction 5.

Measure resistance (Volume

1.

If less than 50 ohms, replace

5.

Short Circuit

engine coolant temperature

Between Engine

3, WP 0369) between pins A

Coolant

and B on engine coolant

sensor. (Volume 3, WP 0412)

Temperature

temperature sensor. (Volume

Restore machine to original

Sensor Pins A and

condition and perform Harness

5, WP 0800, Figure 69) Note

B.

Diagnostic Mode Test.

reading.

(Volume 3, WP 0345)

2.

If greater than 50 ohms,

reconnect all connectors.

Problem was not found and

may have been missed during

troubleshooting. Restart

procedure at Malfunction 1.

Visually inspect engine wiring

1.

If damaged or has loose

6.

Engine Wiring

harness connector T04

sockets, repair connector T04

Harness Connector

T04 Has Damage or

(Volume 5, WP 0800, Figure

(Volume 4, WP 0511) or

Loose Sockets.

69) for damage or loose

replace engine wiring

sockets.

harness. (Volume 4,

WP 0510) Restore machine to

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

2.

If not damaged or does not

have loose sockets, proceed to

Malfunction 7.

0033-3