TM 5-3805-294-23-1

0104

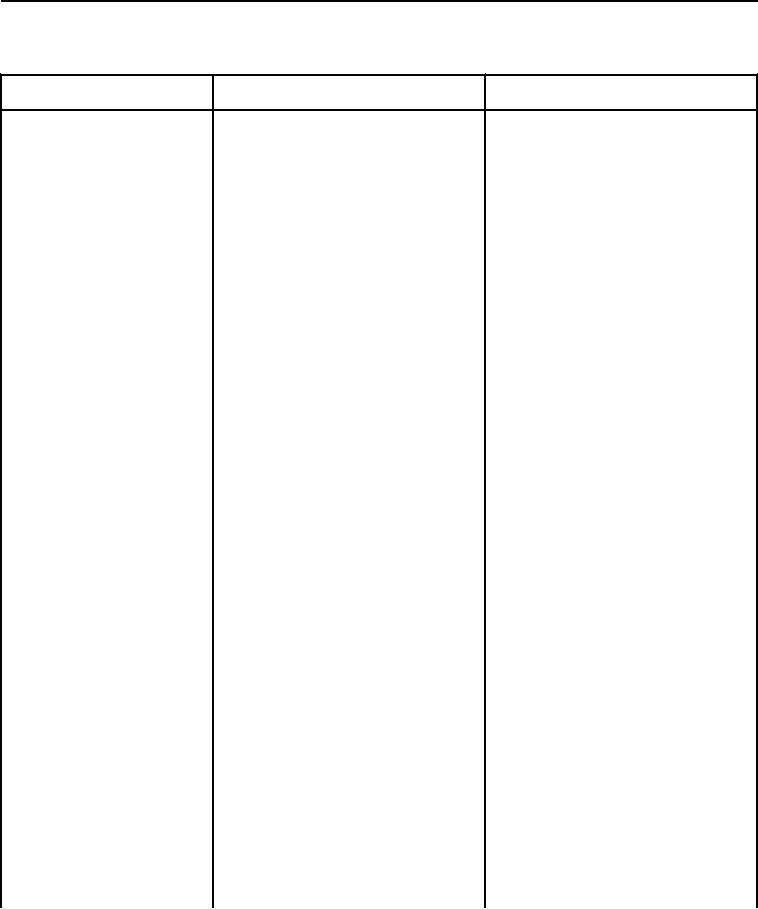

Table 1. DTC 1638.09 - Hydraulic Oil Temperature Message Not Received or Timed Out - Continued.

Test or Inspection

Corrective Action

Malfunction

Visually inspect main

1.

If damage or has bent pins,

3.

Main Controller Has

controller (Volume 5,

replace main controller.

Damage or Bent

Pins.

WP 0800, Figure 217) for

(Volume 4, WP 0517) Restore

damage or bent pins.

machine to original condition.

Clear and refresh DTCs.

(Volume 3, WP 0362)

2.

If not damaged or does not

have bent pins, proceed to

Malfunction 4.

1.

Remove ICF. (Volume 4,

4.

Connector X34 Has

Damage or Loose

WP 0513)

Sockets.

2.

Visually inspect connector X34

1.

If damage or has loose

for damage and loose

sockets, replace cab wiring

harness. (Volume 4,

sockets. (Volume 5, WP 0800,

Figure 98)

WP 0504) Restore machine to

original condition. Clear and

refresh DTCs. (Volume 3,

WP 0362)

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 5.

Visually inspect ICF (Volume

1.

If damaged or has bent pins,

5.

ICF Has Damage or

replace ICF. (Volume 4,

Bent Pins.

5, WP 0800, Figure 98) for

damage or bent pins.

WP 0513) Restore machine to

original condition. Clear and

refresh DTCs. (Volume 3,

WP 0362)

2.

If not damaged or does not

have bent pins, proceed to

Malfunction 6.

Measure resistance (Volume

1.

If continuity is present,

6.

Open Circuit

proceed to Malfunction 7.

Between Connector

3, WP 0369) between

X34 Socket 5 and

connector X34 socket 5

If continuity is not present,

2.

Connector X30

(Volume 5, WP 0800, Figure

replace cab wiring harness.

Socket 4.

98) and connector X30 socket

(Volume 4, WP 0504) Restore

4. (Volume 5, WP 0800,

machine to original condition.

Figure 96) Note reading.

Clear and refresh DTCs.

(Volume 3, WP 0362)

0104-3