TM 5-2420-230-24-1

Table 3-6. Unit Troubleshooting Table. -- Continued

Malfunction

Test or Inspection

Corrective Action

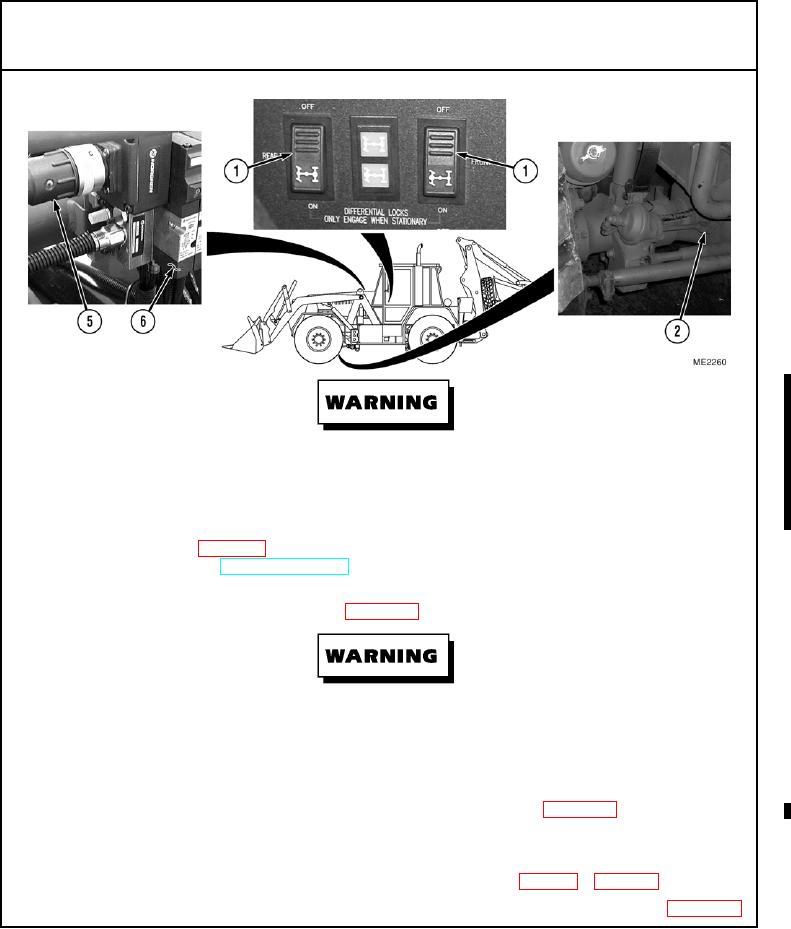

DIFFERENTIAL LOCK WILL NOT ENGAGE. -- CONTINUED

Ensure air pressure is drained to 0 psi (0 kPa) before taking off any air components. If pressure is not

released, components could blow off and harm personnel. The IHMEE air system is pressurized to

119 psi (820 kPa). Do not drain air from a tank with any part of body in air spray path. Skin

embolisms and/or debris in eyes can occur from released pressure. Failure to comply may result in

injury or death to personnel.

Step 3.

Drain air system (Para 15-4) and remove air lines (5) at solenoid block (6). Start engine and allow air

pressure to build (TM 5-2420-230-10). Observe for air after an assistant put DIFFERENTIAL LOCKS

switches (1) in ON position.

If air is present, replace solenoid (Para 12-34).

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or tools contact positive electrical circuits, a

direct short may result. Damage to equipment and injury or death to personnel may occur.

Step 4.

With DIFFERENTIAL LOCKS switches (1) in ON position, remove wires PJ38-Y and PJ38-Z at solenoid

block (6), and ground to vehicle chassis (refer to FO-3). Have an assistant observe differential lock

actuator clevis (2) for movement or engagement.

If differential lock actuator clevis (2) moves, replace wire harness (Para 12-27).

Step 5.

With DIFFERENTIAL LOCKS switches (1) in ON position, check for 18 to 24 Vdc at wires 291 and 292

on solenoid block (6) (refer to FO-3).

If proper voltage is present, notify Direct Support maintenance (Para J-8 or Para J-14).

If proper voltage in not present, replace faulty DIFFERENTIAL LOCKS switch(s) (1) (Para 12-14).

3-107

Change 1