TM 5-2420-230-24-1

Table 3-6. Unit Troubleshooting Table. -- Continued

Malfunction

Test or Inspection

Corrective Action

57.

AIR DRIER CONSTANTLY CYCLING OR PURGING.

Ensure air pressure is drained to 0 psi (0 kPa) before taking off any air components. If pressure is not

released, components could blow off and harm personnel. The IHMEE air system is pressurized to

119 psi (820 kPa). Do not drain air from a tank with any part of body in air spray path. Skin

embolisms and/or debris in eyes can occur from released pressure. Failure to comply may result in

injury or death to personnel.

Step 1.

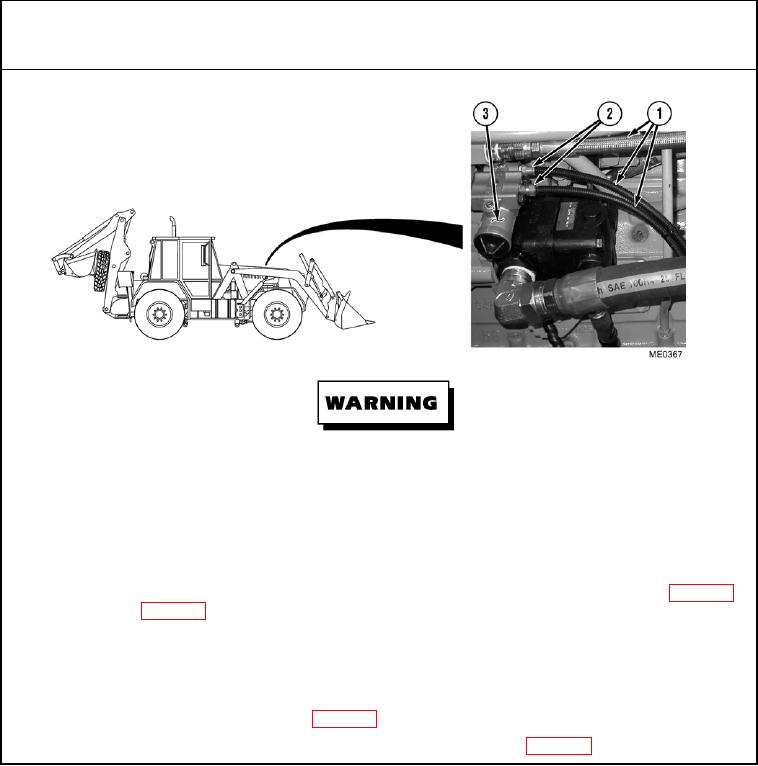

Check air system for leaks in lines (1) and fittings (2).

If a leak is present, tighten loose connection, or replace defective fittings (2) or lines (1) (Para 15-5 or

Step 2.

Check governor (3) for leaks and ensure governor has correct cut-in/cut-out pressures of

120-125 psi (827-862 kPa).

If governor (3) cut-in and cut-out pressures are incorrect, adjust to correct specification of

120-125 psi (827-862 kPa) (Para 15-9).

If governor (3) is defective or will not adjust, replace governor (Para 15-9).