TM 5-2420-230-24-1

Maintenance & Service Manual

R & HR32000 3 & 6 Speed LD

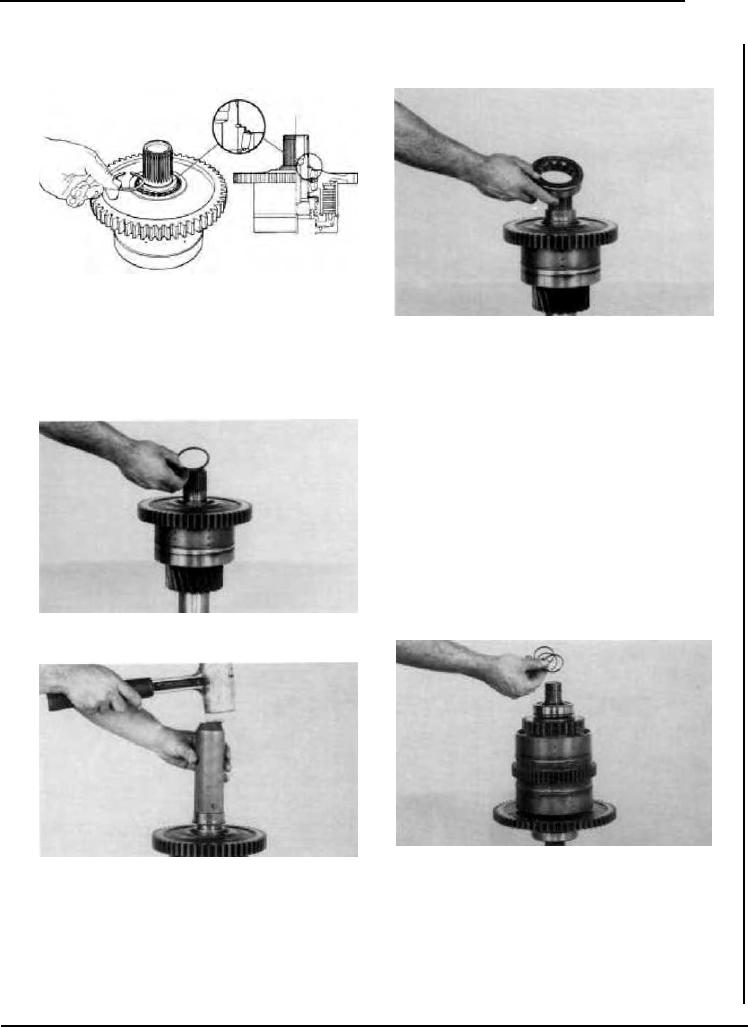

Figure 99

Install low clutch taper bearing retainer ring.

Figure 102

Position front bearing on clutch shaft inner race. NOTE: Bearing

NOTE: Retainer ring is selected at assembly for proper

could be installed in transmission case before installing clutch.

thickness. A snap ring kit is available. Select the thickest

of the three rings in the kit that can be fitted into the snap

ring groove to assure a proper taper bearing tightness.

Check ring as shown for tight ring to bearing fit.

REVERSE AND 3RD CLUTCH

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY

(Reverse being disassembled)

Figure 100

Position ring retainer over retainer ring.

Figure 103

Figure 101

Remove clutch shaft piston rings. NOTE: Some units will

Install clutch shaft front bearing inner race with large diameter

have Teflon piston rings and expander springs, see page

of race down.

79 for proper piston ring installation.

--18--