TM 5-2420-230-24-1

Maintenance & Service Manual

R & HR32000 3 & 6 Speed LD

NOTE: Each disc spring assembly is made up of selected

springs to precisely match each part within this assembly.

Failure to replace all piston return springs can result in

unequal deflection within the spring pack. The result of

this imbalance may adversely affect overall life of springs.

The disc spring packs are to be used as complete assem-

blies and care should be taken not to intermix the individ-

ual disc springs with disc springs in another clutch or disc

spring pack.

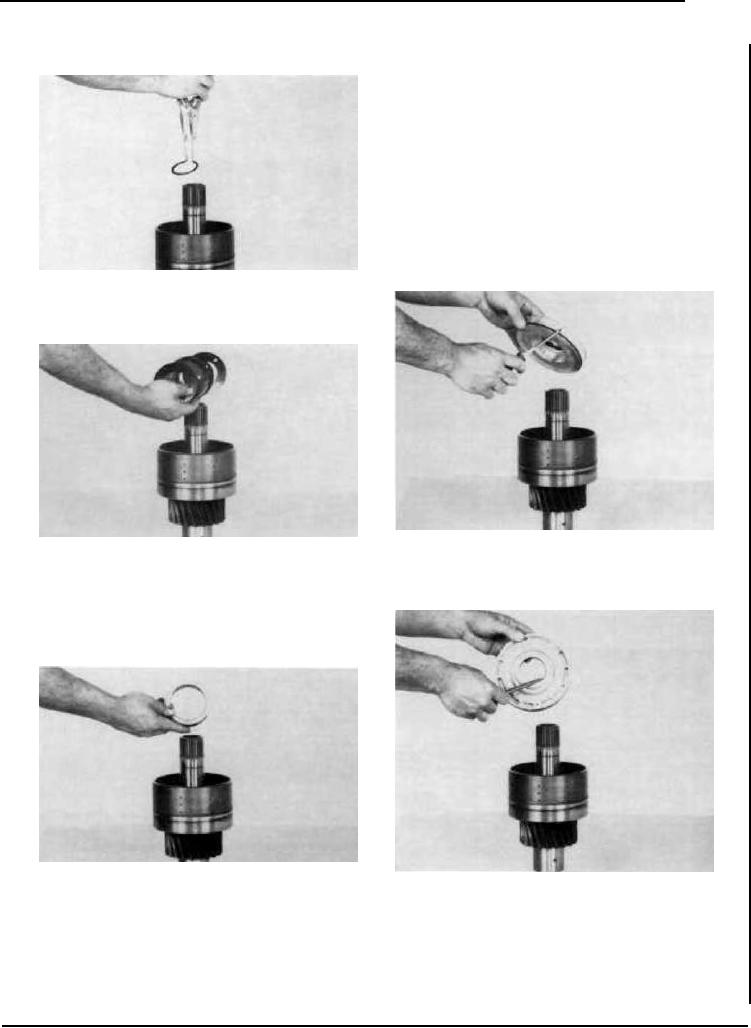

1ST SPEED CLUTCH REASSEMBLY

Figure 82

Remove return disc spring retainer ring.

Figure 85

Figure 83

Install clutch piston outer seal ring.

Remove piston return disc spring. NOTE: Disc springs in

the low clutch are different than springs in the forward and

reverse clutch. Do not mix low clutch springs with for-

ward and reverse springs (see note at top of page). Non

modulated units will have return springs in forward &

reverse clutches.

Figure 84

Figure 86

Remove return spring to piston spacer. Turn clutch over and tap

Install clutch piston inner seal ring. Install piston into clutch

clutch shaft on a block of wood to remove clutch piston.

drum. Use caution as not to damage seal rings.

See cleaning and inspection page.

--15--