TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 19

REFITTING DRIVE HEAD INTO AXLE Cont.

19.6

Fit air chamber (35) onto mounting plate and secure into position with locknuts (31) and washers (32).

Note :-

If new air chamber (54) is to be used, the push rod needs to be cut, prior to fitting, to

same length as on original air chamber. This is because air chamber manufacturer

supplies chambers with push rods to suit all applications.

When fitting diff. lock air chambers ensure that air chamber push rod is fitted in line

and operates at 90 to mounting bracket.

This is to ensure smooth operation and avoid jamming up problems in service.

19.7

Assemble the locknut (38) and yoke (39) onto the push rod end.

19.8

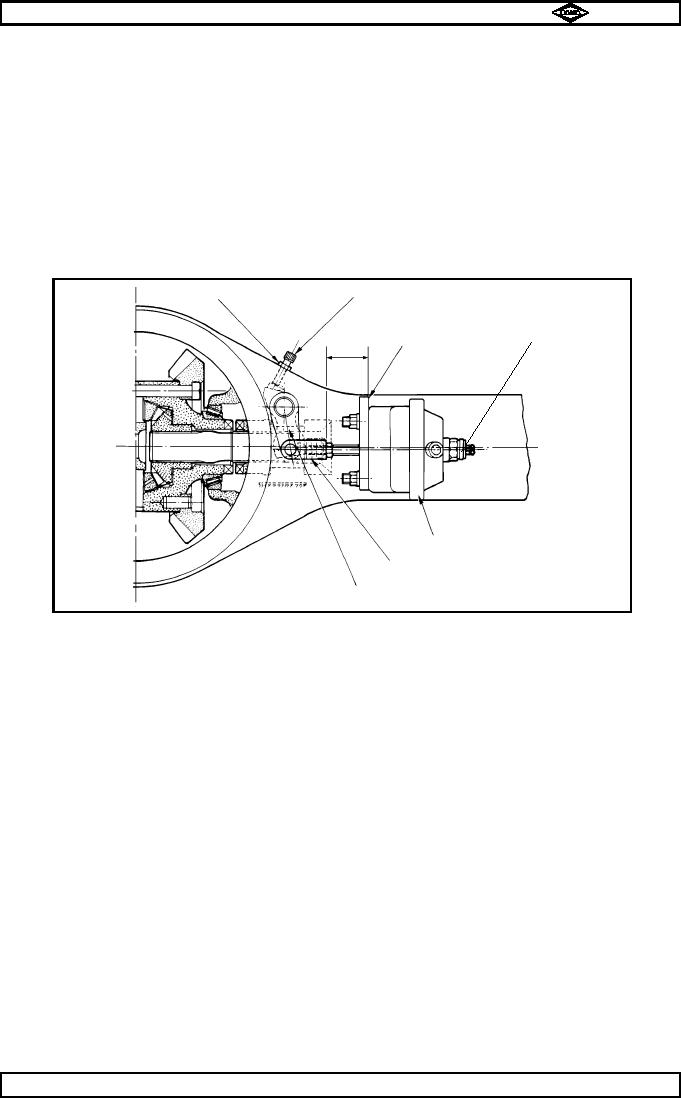

Screw yoke onto push rod until distance from air chamber mounting face to push rod is

11mm - see fig. no.16.

TP76

Item 28

Item 29

Mounting face

Item 34

11mm

Item 35

Item 39

Item 22

Fig. No.16

19.9

Secure yoke (39) with locknut (38).

19.10

Connect diff. lock switch (34), if fitted, and air supply to air chamber (35).

19.11

Check air chamber to yoke distance with air in system.

SECTION 20

DIFF LOCK SETTING PROCEDURE.

20.1

Engage diff. lock then check that lock is fully engaged by rotating one hub, if lock is engaged, other hub

will rotate in same direction.

20.2

Fit stop screw (29) and locknut (28).

Screw stop screw into casing until contact with operating lever is felt.

20.3

Disengage diff. lock.

Give stop screw (29) one half turn clockwise, then lock in position with locknut (28).

20.4

20.5

Check disengagement as follows :-

Rotate one hub and observe direction of other hub.

If lock is disengaged hubs will rotate in opposite directions.

Page No.C23

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-87