TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 22

FINAL ASSEMBLY / ADJUSTMENTS

22.1

Clean interfaces between Hub and brake drum then with brake drum (2 - FH55) suitably supported,

slide into position on hub (16- FH55).

Note :-

Interfaces must be free from dirt , including liner material debris, rust and paint.

Failure to keep interfaces clean, can and will cause brake drum to distort upon

tightening of wheel nuts. For further details see BS AU50 : Part 2 : Section 7A : 1995.

TP1148

Clean interfaces

Clean interfaces

Fig.No.17

22.2

Fit brake drum retaining setscrew (70 - FH55) and tighten to 72 - 80lbs. ft. (98 - 108Nm.).

22.3

Repeat operations 22.1 and 22.2 for other hub unit.

22.4

Re-connect prop shafts to coupling flange (2).

22.5

Refit drain plugs and refill axle with clean gear oil as stated in lubrication section at front of this manual.

22.6

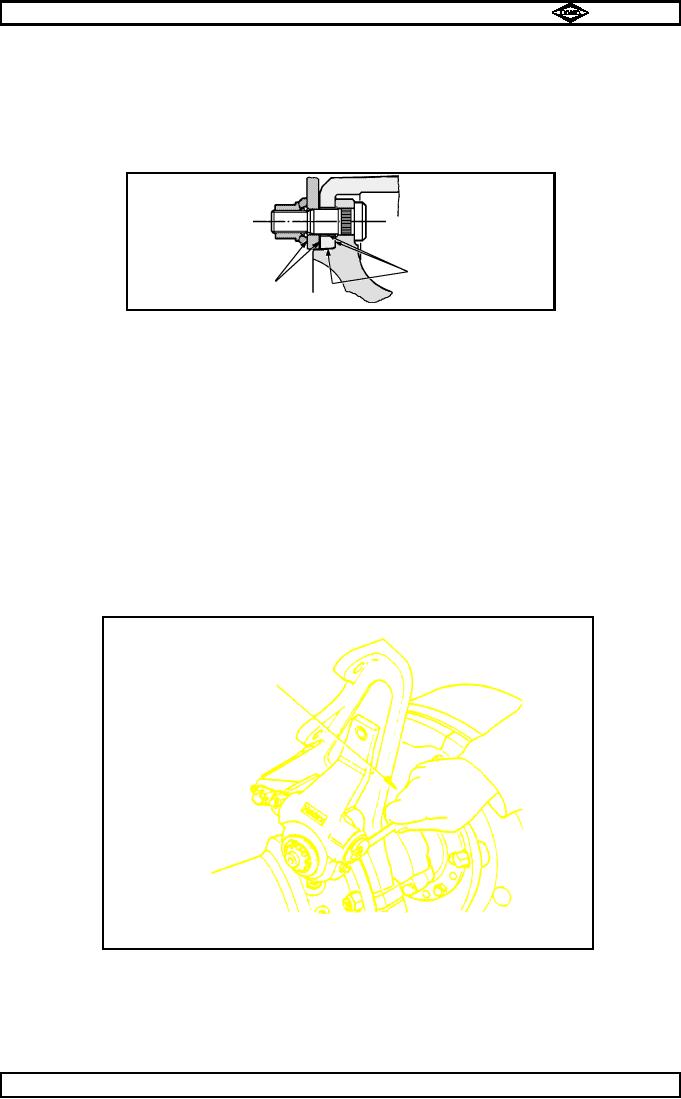

Adjust brakes as follows :-

a)

Turn adjusting screw on slack adjuster (91 - FH55) clockwise until brake linings are hard

up against brake drum, then back off adjusting screw by 3/4of a turnas shown

in fig. no. 18.

b)

Check function of slack adjuster by performing a few brake applications.

Adjustment can then be seen when adjusting screw rotates clockwise on return stroke.

TP31

Turn spanner clockwise

to adjust shoes

against brake drum.

Fig. No.18

22.7

Refit road wheels, securing with wheel nuts (1 - FH55) and tighten nuts to

475 - 525lbs.ft. (644 - 712Nm.).

22.8

Remove axle supports, then lower vehicle to ground.

22.9

Remove chocks and lifting equipment.

Page No.C25

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-89