TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SEQUENCE OF OPERATIONS TO BUILD HUB REDUCTION UNIT ONTO AXLE ARM

(THE BRAKE ASSEMBLY WILL BE IN SITU)

with grease (Shell Retinax LX or equivalent) using a bearing packer or manually

kneading grease between rollers, race and cage before setting and rotated whilst being

set.

SECTION 11

HUB AND ANNULUS RE-ASSEMBLY

11.1

Using suitable bumper tool, fit outer and inner hub bearing cups (22 & 71) into their relevant bores in

hub (20).

11.2

Place hub (20), outer end down on bench and place lightly oiled inner hub bearing cone (22A) into inner

hub bearing cup (22).

11.3

Fit hub oil seals (68) as follows:-

Note :-

Before fitting seals, wipe hub bore (20) clean, also outside diameter of seal.

Smear a thin coat of EP 90 oil, in hub bore (use no sealants).

a)

b)

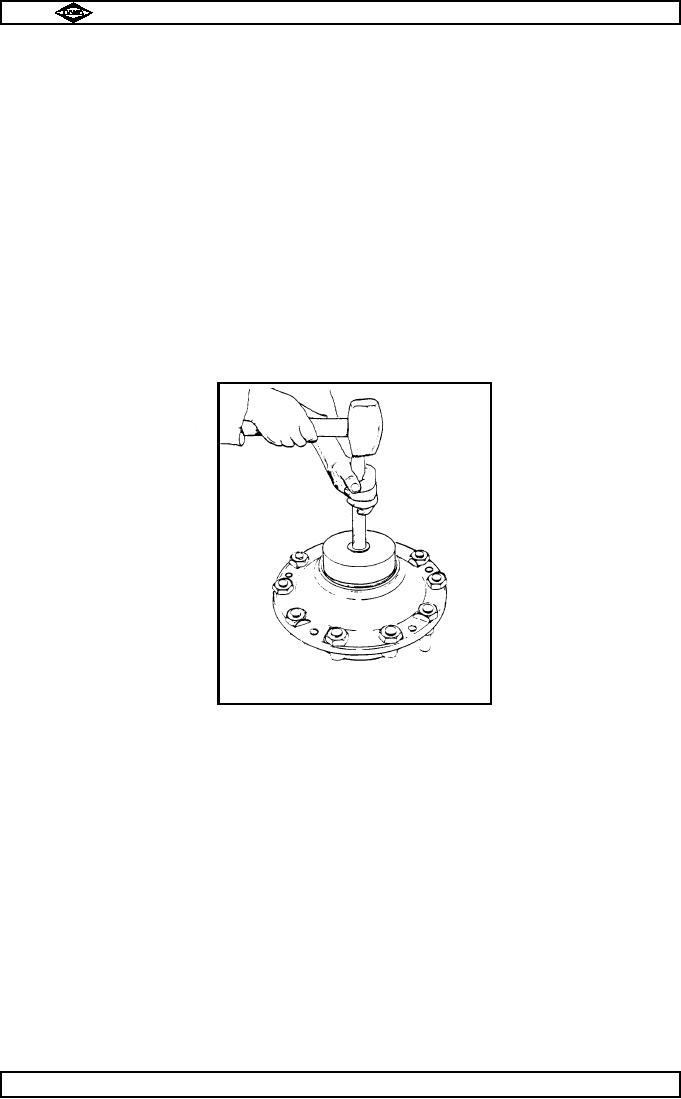

Using correct service tool (E552) and a rawhide mallet, drive first seal into hub bore,

sealing lip first until it abuts its shoulder in hub bore. See fig.6.

Extreme care must be taken during this operation so as not to damage seals.

TP90

Fitting of oil seal (method)

Fig. No. 6

c)

Similarly using correct service tool (E553) and a rawhide mallet, drive second seal into

hub bore, sealing lip first until it abuts first seal in hub bore.

Fill cavity between seals (68) for 240o of circumference with a high melting point grease

11.4

(BP Keenomax L2 or equivalent).

If any wheel studs have been removed, refit into hub (20) fully home, ensuring that they are 90o to hub

11.5

outer face.

11.6

If annulus gear (17) and annulus carrier (18) have been separated, re-assemble as follows :-

a)

Check annulus gear dowels (74) for wear / damage, remove and replace if required.

b)

Fit annulus gear (17) onto annulus carrier (18) and secure with annulus gear setscrews

and annulus gear setscrew lockplates (73), ensuring that two of lockplates are fitted

across dowel holes to prevent dowels from working out in service.

c)

Tighten setscrews to 105 - 150 lbs. ft. (142 - 203Nm.) and lock them in position by

bending over a portion of lockplates up against a convenient flat on setscrew head.

Page No.D11

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-103