TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 11

HUB AND ANNULUS RE-ASSEMBLY Cont.

11.7

Press outer hub bearing cone (71A) onto annulus carrier (18).

11.8

If oil seal wear sleeve (56) has been removed, then a new sleeve should be fitted as follows :-

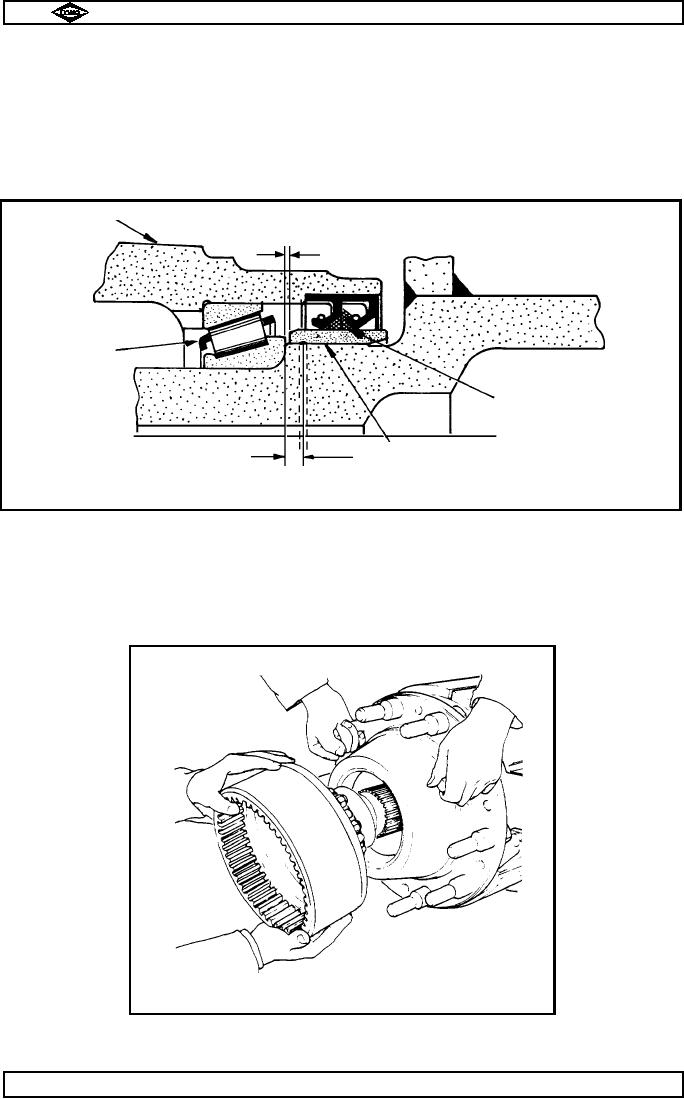

a)

Clean mating surfaces of sleeve and axle stub (56 & 55) with Loctite 7070 or similar

degreasing agent.

b)

Apply a bead of Loctite No.275 sealing compound completely around axle stub (55),

approx. 1/4" from inner bearing shoulder as shown in fig. no.7.

c)

Using service tool No. E398, knock wear sleeve (56) into position on swivel stub (55).

d)

Allow 2 hours for loctite to cure.

TP325

Hub

0.060"

Hub bearing

Gap between oil seals

to be filled with

high melting point grease

on assembly.

1

/4"

Wear sleeve

Part section through hub

Fig. No.7

11.9

Lightly oil hub inner bearing (22 / 22A), then ease hub onto axle arm (55) such that hub

bearing (22 / 22A) slides onto its location diameter, also seals (68) are felt to contact their location

diameter.

Note :-

Throughout this operation hub MUST be supported so as not to be left 'hanging' at any

point.

11.10

With hub held in place by an assistant or suitably held in a sling, then lightly oil hub outer bearing

cone (71A), and offer annulus assembly to axle arm (55). See fig. no.8.

TP91

Hub held in place - offering up annulus

Fig No. 8.

11.11

Fit axle tube nut pinch bolt and nut (76 & 75)onto axle tube nut (16). Tighten pinch bolt nut finger tight.

11.12

Fit axle tube nut assembly onto axle arm (55), using service tool no. E399, and tighten nut hard.

Page No.D12

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-104