TM 5-2420-230-24-1

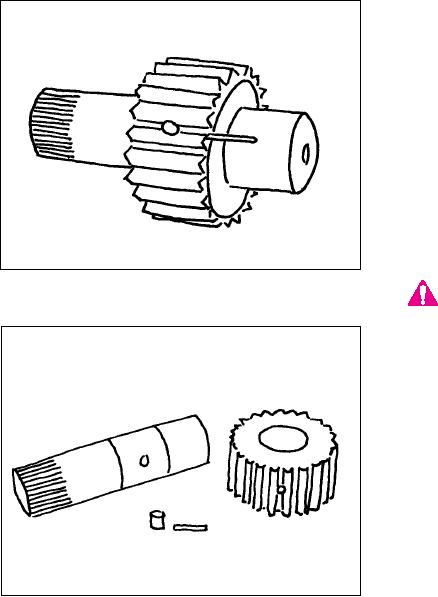

REPAIR OUTPUT SHAFT AND PINION (M110 ONLY)

1. The pinion gear is located and held in place on the

output shaft with a retaining pin. A roll pin

through the pinion gear will keep the retaining pin

from backing out of place. To remove the pinion

gear, punch out the roll pin and drill out the retain-

ing pin. Press the pinion gear off the output shaft

(Figure 111).

NOTE:

If the retaining pin cannot be drilled out, it can be

sheared off with approximately 10 tons of pressure

on a hydraulic press. Drive half the pin out of the

pinion gear and drill the remaining half out of the

shaft.

Figure 111

WARNING

USING A HYDRAULIC PRESS IMPROP-

ERLY CAN CAUSE PIECES OF METAL

TO BREAK OFF OR SHATTER. PIECES

O F METAL UNDER PRESSURE CAN

C AU S E SERIOUS INJURY. ALWAYS

WEAR SAFETY GLASSES AND FOLLOW

ALL SAFETY AND OPERATING PROCE-

DURES PROVIDED BY THE HYDRAULIC

PRESS MANUFACTURER.

2. To reassemble the pinion gear to the output shaft,

align the timing arrows on the output shaft to the

arrow on the pinion gear. Press the gear on to the

shaft splines until the locating pin can be driven

Figure 112

through the gear and into the locating hole in the

shaft. Install the roll pin through the gear

(Figure 112).

K-84