TM 5-2420-230-24-1

REASSEMBLY

CLEANING & INSPECTION

Cleaning

Cleanliness is important. Dirt and foreign material that gets into the steering system during repair operations can

cause damage or a possible steering malfunction at a later date. Due to the close tolerances between mating parts

it is best to have all parts at the same temperature for reassembly.

Clean the machined parts individually to avoid damage caused by "bumping" together. Use clean solvent to

wash parts. Dry the parts with compressed air. Nicks or burrs must be removed with a fine hand stone before

assembly. Use clean lubricant to coat parts for assembly.

All hoses, lines and the reservoir should be cleaned before reinstalling a repaired steering gear or after pump

replacement. Replace the filter element or cartridge.

Inspection

Make a careful visual inspection of all steering gear parts. Replace worn parts as well as any parts that show

signs of stress or fatigue.

DANGER

STEERING GEARS THAT HAVE BEEN DAMAGED IN AN ACCIDENT MUST BE

REPLACED. IMPACT LOADS TRANSMITTED THROUGH THE FRONT AXLE

AND STEERING LINKAGE INTO THE STEERING GEAR CAN STRESS PARTS

TO A POINT JUST SHORT OF FAILURE. FURTHER USE IS UNSAFE AND THE

STEERING GEAR ASSEMBLY AND PITMAN ARM MUST BE REPLACED. DIS-

T O RT E D PITMAN ARMS, T W I S T E D SECTOR SHAFTS, B RO K E N OR

CRACKED RACK AND PINION GEAR TEETH ARE SOME SIGNS OF IMPACT

DA M AG E . B RO K E N OR DAMAGED MOUNTING BRACKETS MUST BE

REPLACED.

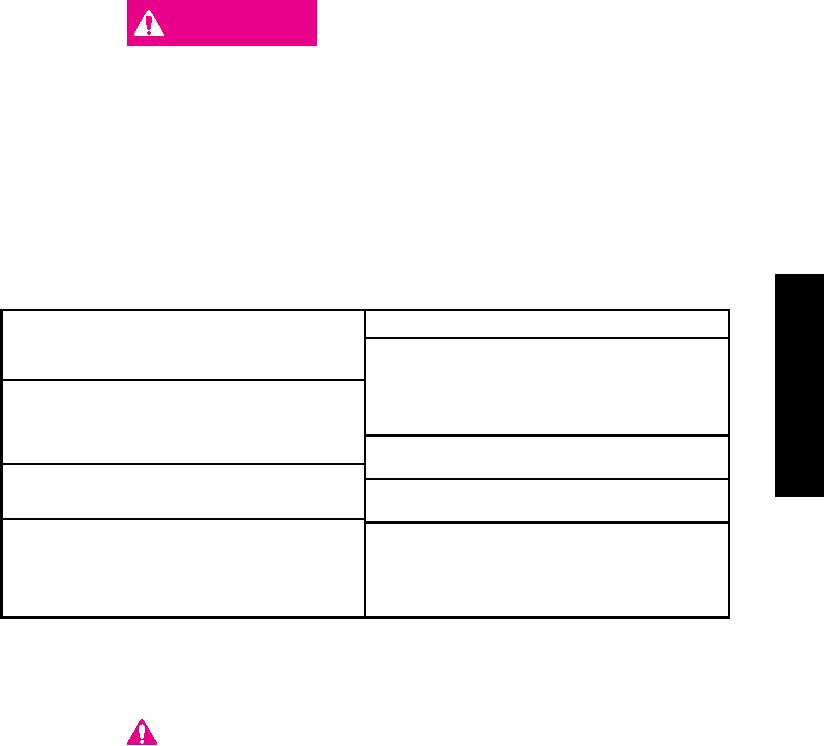

Steering gear parts inspection may show problems in other areas of the steering system. To avoid repeat prob-

lems inspect all parts carefully. Listed below are the more common problems you may see during steering gear

inspection along with their possible cause. This information should be considered carefully when repairing low

mileage vehicles. Remember it is more important to repair the cause than the results.

R

E

1. Operating temperatures too high

1. Accident damaged

Parts Discolored (blue)

Broken Housing

A

2. Steering column binding

3. Hydraulic supply pump

S

1.

Foreign material entry

Housing or Piston Scoring

malfunctioning

2.

Severe overloading

(Also see following

S

3.

Incorrect lubricant used

NOTE)

1.

Incorrect lubricant use

4.

Excessive temperature (over

E

Sector Shaft (Roller

2.

Excessive temperature

250)

bearing wear)

M

3.

Overloading the axle

5. Pump damaged

4.

Contaminated lubricant

B

5.

Impact damage

1. Foreign material in system

Thrust Bearings

L

2. Excessive overloading

(pitted, rough)

1. Impact damages

Actuating Shaft

Y

(ball thread brinelled

1. Impact damage

Thrust Bearings

or dented)

2. Incorrect repairs

(broken or distorted)

1.

Incorrect lubricant used

Actuating Shaft

1. Incorrect installation

Piston Rings (cut,

2.

Overloading

(thread wear)

2. Incorrect assembly

pinched, sheared or worn)

3.

Insufficient operating pressure

4.

Insufficient oil flow

5.

Continued operation at high

temperature

Note on scoring

Minor scoring and scuffing of the piston and housing of the steering gear is normal. During operation at rela-

tively high pressure and flow rates, this minor scoring will not affect the safety or operation of the steering gear.

Minor scoring should be polished with a fine hand stone or crocus cloth.

CAUTION

The cylinder bore should not be honed or bored out. This will increase internal leakage.

K-88