TM 5-2420-230-24-1

7.

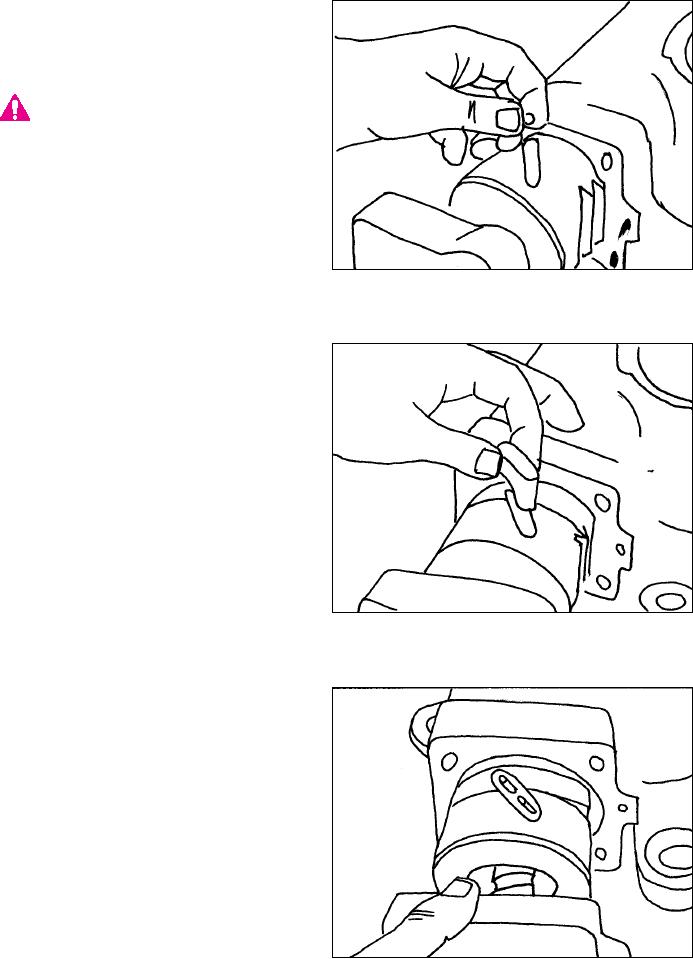

While supporting the bearing cap assembly

with your hand, load the 24 steel balls in the

ball guide. Slowly turn the bearing cap

assembly inward while feeding the steel balls

until all the steel balls are used (Figure 126).

CAUTION

Do not attempt to back the actuating shaft

out of the piston during this process. This will

cause the steel balls to bind on the actuating

shaft and shaft damage may result.

IMPORTANT:

Both halves of the ball guide must be held

down when loading the balls to prevent the

balls from coming out of their track.

Figure 126

8.

Install a new O-ring on the ball guide retainer

and coat it with a small amount of grease.

Insert the retainer over the ball return guide

and into the ball guide cavity (Figure 127).

Figure 127

9.

It will be necessary to tap the ball guide

retainer into place with a soft hammer

(Figure 128).

NOTE:

When properly installed the retainer will be

flush with the piston contour.

Figure 128

K-91