TM 5-2420-230-24-2

Section 1 - Cylinder Block - Group 1

Cylinder Block - Inspection (1-01)

B Series Shop Manual

Page 1-15

After rinsing with clean solvent, use compressed air to dry

the block.

Cylinder Block - Inspection (1-01)

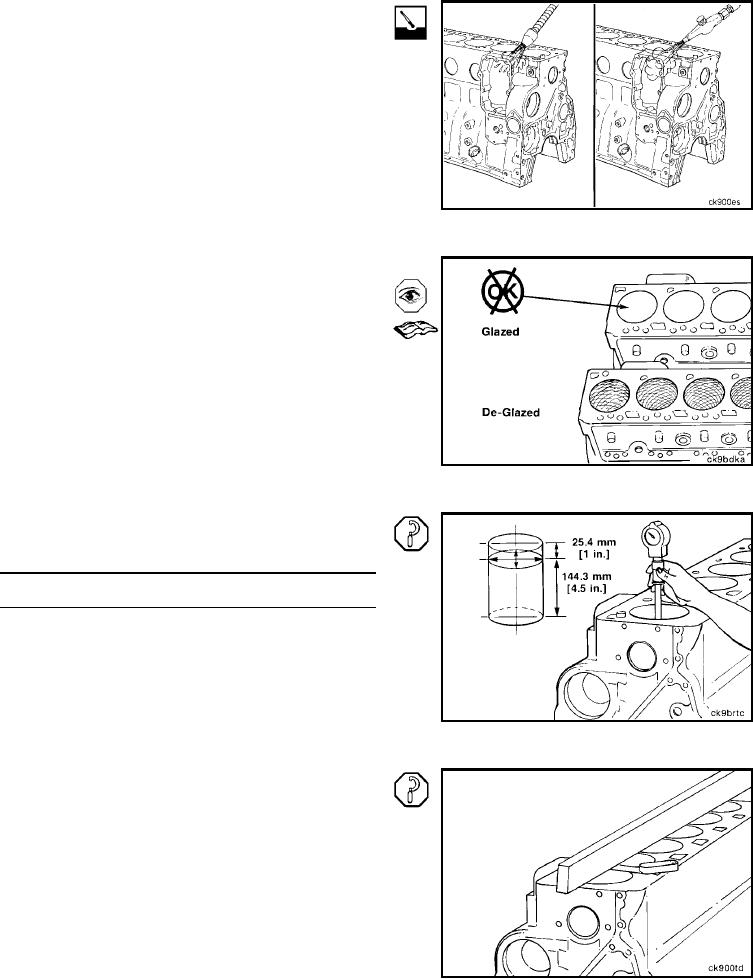

Inspect the cylinder bores for glazing.

A surface without glaze will have a crosshatched appear-

ance with the lines at 25 to 30 degree angles with the top

of the cylinder block.

If de-glazing is required, refer to procedure number (1-05).

Inspect the cylinder bores for damage or excessive wear.

Measure the cylinder bores.

Diameter

mm

in

102.000

MIN

[4.0161]

102.116

MAX

[4.0203]

Out-of-Roundness: .038 mm [.0015 in]

Taper: 0.076 mm [.003 in]

Oversize pistons and rings (0.5 mm and 1.0 mm oversize)

are available for re-bored cylinder blocks.

Measure the cylinder block overall flatness:

End-to-End

0.076 mm [0.003 in.]

Side-to-Side 0.051 mm [0.002 in.]

Visually inspect for any localized dips or imperfections. If

present, the cylinder head deck must be reground.

L-218