TM 5-2420-230-24-2

Expansion and Pipe Plug - Installation (1-06)

Section 1 - Cylinder Block - Group 1

Page 1-20

B Series Shop Manual

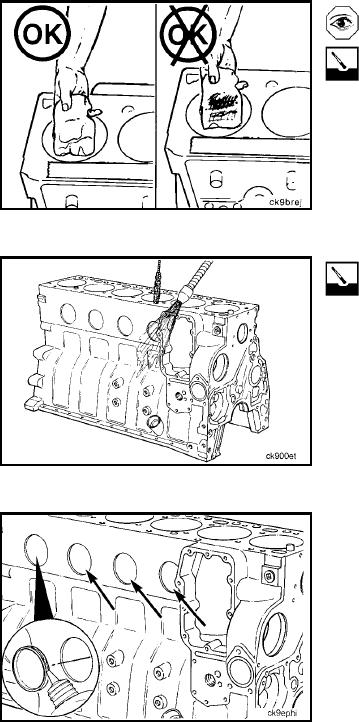

Check the bore cleanliness by wiping with a white, lint

free, lightly oiled cloth. If grit residue is still present,

re-clean.

Wash the block in solvent.

Use a brush to clean all oil passages.

Expansion and Pipe Plug - Installation

(1-06)

All expansion plug bores in the block are machined to a

standard english dimension (i.e., 11/16 in, 1-1/4 in, etc.).

To achieve the correct press fit of the expansion plug in

the bore, the expansion plug must be larger than the bore

diameter and the expansion plug driver must be smaller

than the bore diameter. Therefore, expansion plugs and

their drivers are not made to a standard english dimen-

sion.

The plug drivers are called out by the dimension of the

bore they are to be used on (i.e., a 1 in driver for 1'' bore).

The expansion plugs are called out by Cummins part

number (a dimension is also listed for reference).

Apply a bead of Three Bond, Part No. 3823494, around

the outside diameter of all expansion plugs before

installing.

L-223