TM 5-2420-230-24-2

Section 14 - Engine Testing - Group 14

Engine Dynamometer Test - Installation of the Engine (14-01)

B Series Shop Manual

Page 14-9

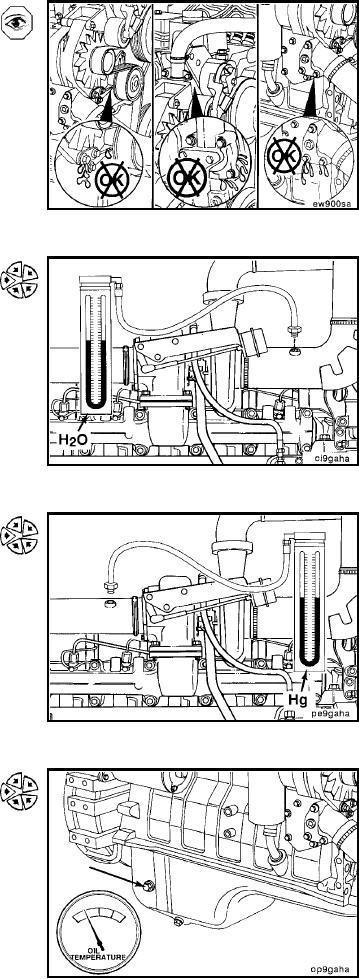

Inspect the engine for coolant leaks at connections, fit-

tings, plates, and plugs. Repair as necessary.

Connect a water manometer to the turbocharger air inlet

pipe to test air restriction.

NOTE: The manometer connection must be installed at a 90

degree angle to the air flow in a straight section of pipe, one

pipe diameter before the turbocharger.

NOTE: A vacuum gauge can be used in place of the water

manometer.

Minimum Gauge Capacity: 760 mm H20 [30 in. H20]

Connect a mercury manometer to a straight section of the

exhaust piping near the turbocharger outlet to check ex-

haust restriction.

NOTE: A pressure gauge can be used in place of the mer-

cury manometer.

NOTE: For automotive applications, a tapped hole is pro-

vided on the inlet side of the catalyst to check exhaust

restriction.

Minimum Gauge Capacity: 254 mm Hg. [10 in. Hg.]

Attach the lubricating oil temperature sensor in one of the

locations on the side of the engine as shown.

Minimum Gauge Capacity:

150C [300F]

L-439