TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Crankshaft Wear Sleeve, Rear (001-067)

Section 1 - Cylinder Block - Group 01

Page 1-113

For a wet flywheel housing, use soap on the outside di-

ameter of the seal case.

For a dry flywheel housing, nothing is required on the

outside diameter of the seal case.

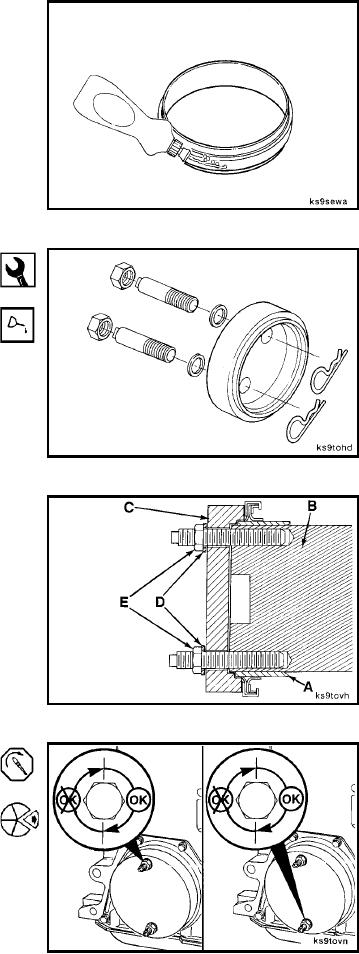

Crankshaft Rear Seal/Wear Sleeve Installation Tool, Part

No. 3824078

Use a service tool, Part No. 3824078, to install oil seal/wear

sleeve assembly. Install two (2) threaded studs into the

crankshaft capscrew holes.

Apply a small amount of clean lubricating engine oil to the

crankshaft, threaded studs, and inside diameter of the

crankshaft rear seal/wear sleeve installation tool.

Position the chamfered end of the wear sleeve (A) onto the

end of the crankshaft (B). Position the counterbore end of

installation tool (C) over threaded studs, and align with

wear sleeve, perpendicular to the end of the crankshaft.

Install the washers (D) and nuts (E) onto the threaded studs.

Alternately tighten the nuts one-half turn until the installa-

tion tool contacts the end of the crankshaft.

NOTE: Do not exceed one-half revolution of each nut to

prevent wear sleeve binding and irregular stretch.

Torque Value: 20 Nm

[15 ft-lb]

Remove the installation tool and threaded studs.

L-791