TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Fuel Lift Pump (005-045)

Section 5 - Fuel System - Group 05

Page 5-79

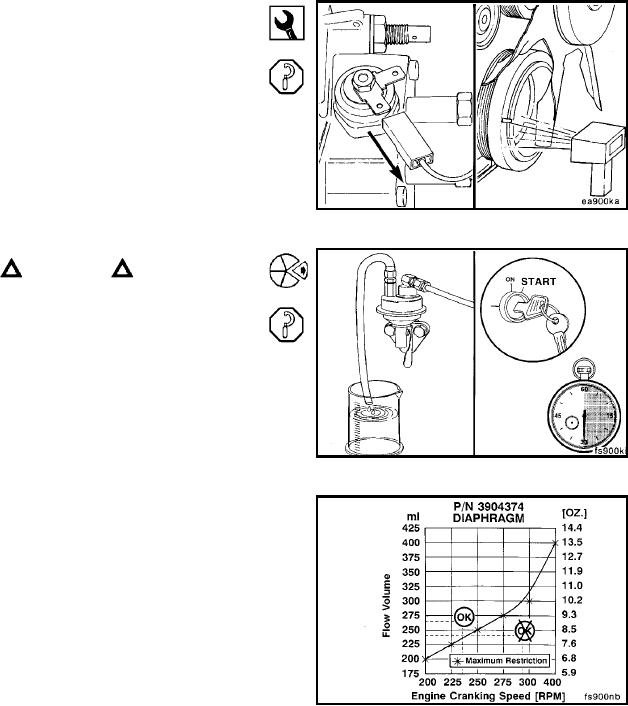

Tachometer, Part No. 3377462

Disconnect the fuel shutdown solenoid wire, and measure

the engine cranking speed with a handheld tachometer

Cummins Part No. 3377462.

CAUTION

Leave the shutdown solenoid disconnected for the fol-

lowing check.

Disconnect the output pressure line from the fuel transfer

pump, and run it into a container.

Measure the fuel transfer pump flow volume while cranking

the engine with the starter for 30 seconds.

Use the chart in the illustration to find the correct flow

volume specification for the diaphragm fuel transfer pump.

Draw a straight vertical line above the measured

cranking rpm

Draw a straight horizontal line from the measured

flow volume to the engine cranking rpm vertical line

to find the intersection point

Any intersection point above the required flow line

indicates an acceptable flow

Any intersection point below the required flow line

indicates unacceptable flow and a defective pump

or too much line restriction.

For example, if cranking speed of the engine is 230 rpm at

a flow volume of 260 ml [8.8 oz], this would indicate a good

pump.

For example, if cranking speed of the engine is 290 rpm at

a flow volume of 240 ml [8.1 oz], this would indicate a bad

pump.

L-939