TM 5-2420-230-24-2

Speed Droop Governor (005-058)

B3.9 and B5.9 Series Engines

Page 5-94

Section 5 - Fuel System - Group 05

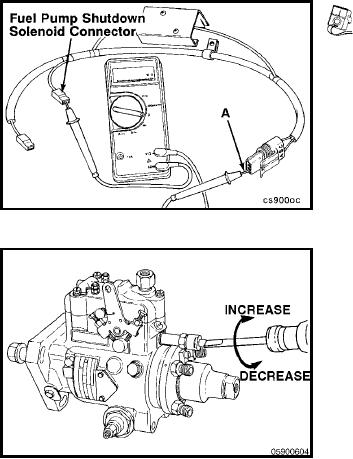

Use a multimeter to perform a continuity check between

port A of the metro-pack connector and the fuel pump

shutdown solenoid connector.

Repair the wire if there is an open circuit.

(Spec = Less than 10 ohms).

Speed Droop Governor (005-058)

Adjust (005-058-029)

Stanadyne DB4 (Generator Application) Speed Droop

Governor

Governor regulation of 3 percent to 5 percent can be at-

tained with the speed droop governor. Precise control of

governor regulation is done by decreasing or increasing

the effective length of the governor control spring; this also

decreases or increases the spring control spring rate. The

governor control spring is threaded into an adjusting cap

assembly and is referred to as the control rod assembly. By

turning the adjusting cap in the clockwise direction, as

viewed from the fuel transfer pump end, the control rod

spring shortens and becomes less sensitive, thereby in-

creasing governor regulation. Turning the adjusting cap in

the counterclockwise direction increases the control rod

spring length and sensitivity, which will decrease governor

regulation.

The external speed droop adjustment screw, located at the

rear of the fuel injection pump housing, controls the gov-

ernor sensitivity. The droop screw adjustment varies the

governor regulation by changing the effective spring rate.

This adjustment will affect both full-load and no-load fre-

quency settings and can require the high-speed stop screw

be reset.

Speed droop adjustments must be made while the engine

is operating. After each adjustment of the droop screw, the

engine must be shutdown briefly in order to allow the

governor spring to unload and the adjusting mechanism to

seek its final position in the spring. Turning the screw in

shortens the control spring, making it less sensitive and

increasing speed droop. Turning the adjusting screw out

has the opposite effect. Speed droop is the fuel injection

pump's ability to respond to changing engine loads.

L-954