TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Lubricating Oil Pan (007-025)

Section 7 - Lubricating Oil System - Group 07

Page 7-17

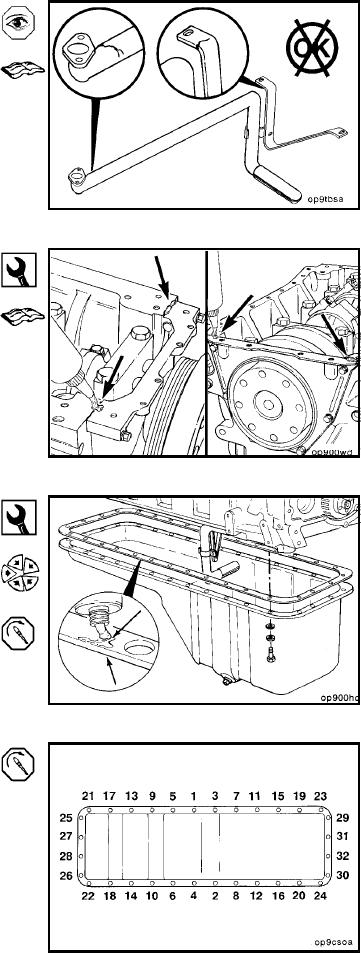

Inspect for Reuse (007-025-007)

Inspect the oil pan, suction tube, and tube braces for dam-

age.

NOTE: If cracks are found, replace the damaged part. Do

not attempt to repair the oil pan by welding.

If the suction tube must be replaced, refer to Procedure

007-035.

Install (007-025-026)

Three-BondTM Sealant, Part No. 3823494

Use Three-BondTM sealant to fill the joints between the

lubricating oil pan rail, gear housing, and rear seal housing.

If the suction tube has been removed, refer to Procedure

007-035 for installation instructions.

10 mm

Three-BondTM Sealant, Part No. 3823494

Apply a 2-mm [1/16-in] bead of Three-BondTM sealant, Part

No. 3823494, to both sides of the new lubricating pan

gasket.

Install the gasket and lubricating oil pan.

Torque Value: 24 Nm

[18 ft-lb]

10 mm

Assemble the washers and capscrews to secure the lubri-

cating oil pan as illustrated.

Tighten all capscrews in the sequence shown in the ac-

companying chart.

Torque Value: 24 Nm

[18 ft-lb]

L-1029