TM 5-2420-232-10

0017

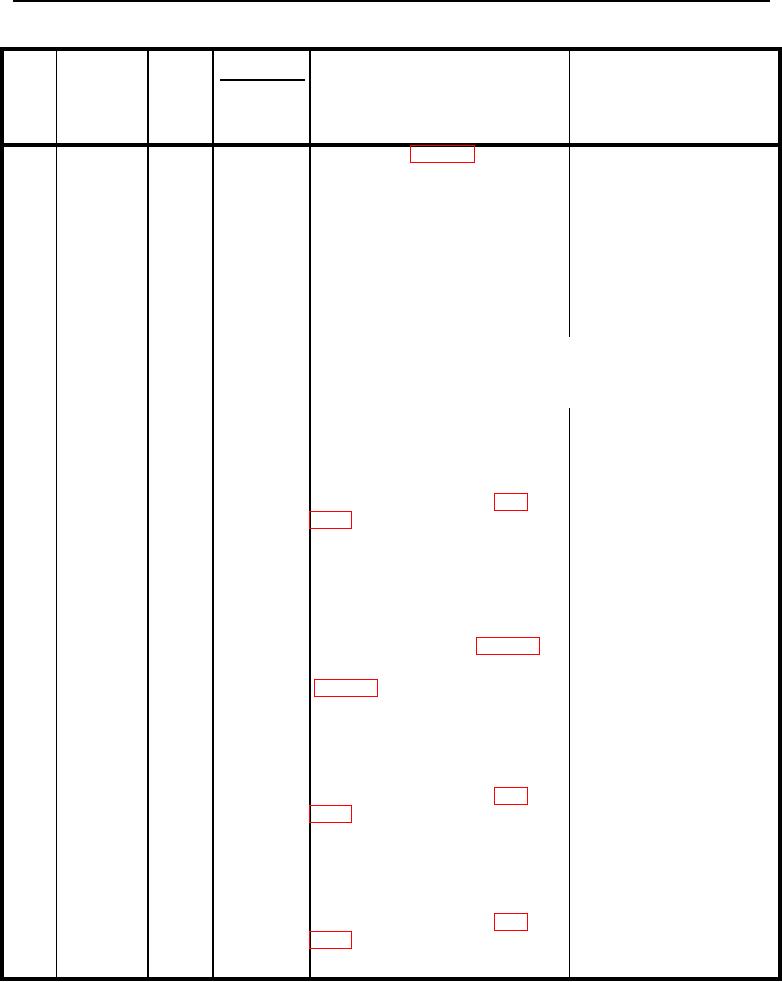

Table 1. Before PMCS - Continued.

LOCATION

ITEM TO

ITEM

NOT FULLY MISSION

CHECK/

MAN-

NO.

CAPABLE IF

PROCEDURE

SERVICE

INVERVAL HOURS

a. Start engine (WP 0005). Observe air Air pressure fails to reach 87 psi

26

Before

Brakes

pressure gauge. Approximately 3 minutes (600 kPa). Warning light or

after the engine has started the gauge

buzzer will not extinguish.

should read a minimum of 87 psi (600

kPa) and the warning buzzer and low

pressure warning light on the EMS unit

must be extinguished.

b. Move the machine forward and apply Brakes are inoperative or pedal

the brakes to see if the machine stops or if binds.

the pedal binds.

NOTE

27

Before

Impact

Wrench

Perform Before PMCS on Item Nos. 27 thru 38 if required for the

mission.

a. Inspect tool for damage, loose

Tool is damaged, has loose

hardware, and leaks.

hardware, or leaks.

b. Inspect hoses and fittings for damage Hose or fitting is damaged or

and leaks.

leaks.

c. Perform operational check (WP

Does not operate properly.

a. Inspect tool for damage, loose

Tool is damaged, has loose

28

Before

Chain Saw

hardware, and leaks.

hardware, or leaks.

b. Inspect hoses and fittings for damage Hose or fitting is damaged or

and leaks.

leaks.

c. Inspect entire chain. Tension and

Chain tension incorrect. Chain is

sharpen chain if necessary (WP 0035).

dull, worn, or damaged.

d. Check operation of automatic oiler

Oiler improperly set.

a. Inspect tool for damage, loose

Tool is damaged, has loose

29

Before

Pavement

hardware, and leaks.

hardware, or leaks.

Breaker

b. Inspect hoses and fittings for damage Hose or fitting is damaged or

and leaks.

leaks.

c. Perform operational check (WP

Does not operate properly.

Hammer Drill a. Inspect tool for damage, loose

Tool is damaged, has loose

30

Before

hardware, and leaks.

hardware, or leaks.

b. Inspect hoses and fittings for damage Hose or fitting is damaged or

and leaks.

leaks.

c. Perform operational check (WP

Does not operate properly.

0017-9

Change 1