TM 5-2420-232-10

0047

ROAD WHEEL REPLACEMENT CONTINUED

Replacing a Road Wheel

00047

WARNING

If, for whatever reason, a wheel stud is replaced, all the studs for that wheel must be replaced as a

set, since the remaining studs may have been damaged. Failure to follow this warning may result in

the road wheel coming loose at convoy speeds, resulting in loss of machine control. This may result

in injury or death to personnel.

Do not use a machine with visible signs of damage to the road wheels or wheel nuts. Failure to

follow this warning may result in injury or death to personnel.

Once in position and the engine is shut down, do not turn on the ignition again until either the road

wheel has been fitted or the axle suitably chocked. The active suspension will cause the axle to

drop if either of these conditions is not met and the ignition is turned on. Failure to follow this

warning may result in injury or death to personnel.

1.

Ensure that the mating faces of the road wheel and axle hub are clean and free of debris. With assistance, position the road

wheel on the wheel studs. Install the wheel nuts and tighten sufficiently to hold the road wheel in place.

2.

Remove the jack stand from under the axle and lower the machine to the ground.

WARNING

The wheel nuts must be torque tightened. Over- or under- torquing may result in wheel nut failure.

Failure to follow this warning may result in injury or death to personnel.

3.

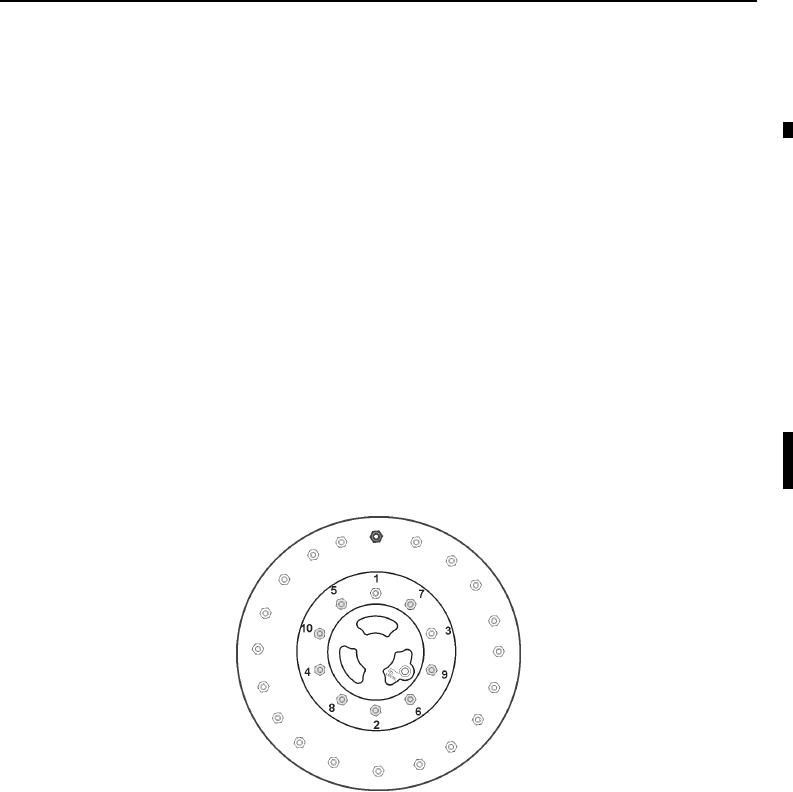

Torque the wheel nuts to 370 lb-ft (500 Nm) in the order shown in Figure 2.

435-1365

Figure 2. Wheel Nuts Tightening Sequence

047

4.

Check and adjust the wheel nuts torque after every 10 hours of operation until they stay correct.

END OF TASK

END OF WORK PACKAGE

0047-3/(4 Blank)

Change 1