TM 5-3805-280-10

Maintenance--Every 250 Hours

CAUTION: High pressure release of fluids from

pressurized system can cause serious burns.

Wait for propel gearbox oil to cool. Keep body

and face away from check plug. Gradually

loosen check plug to release air to relieve

pressure.

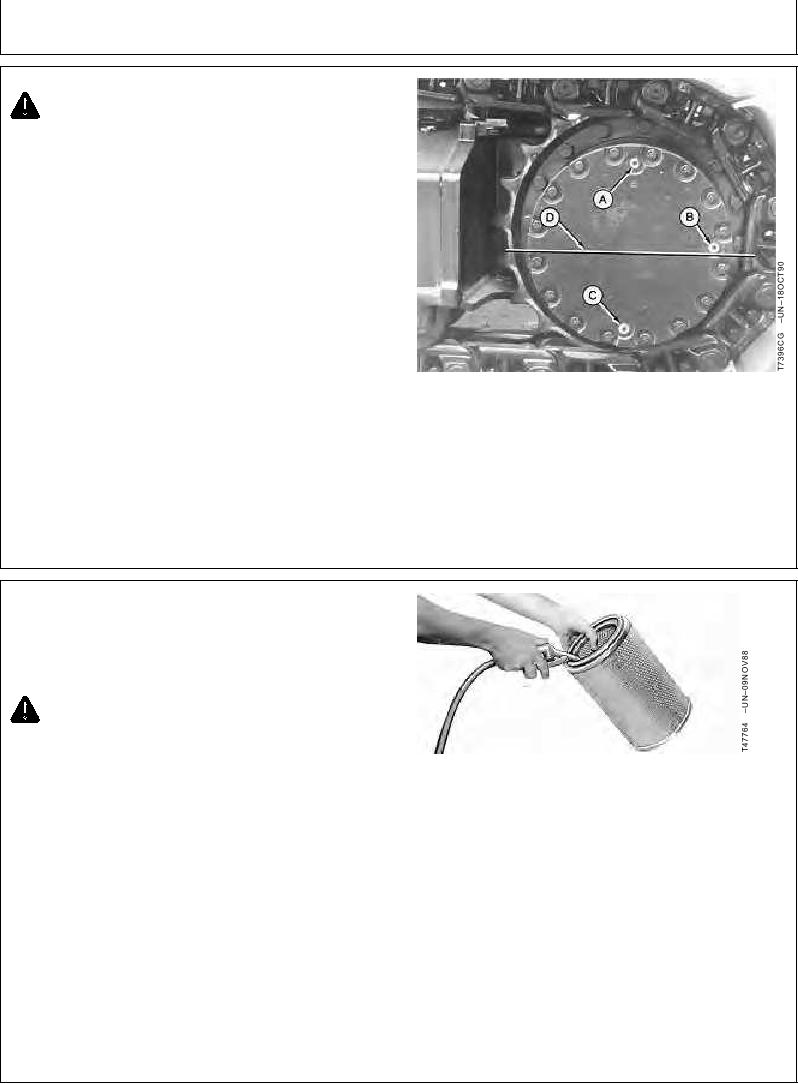

9. After propel gearbox has cooled, slowly loosen check

plug (B) to release air to relieve pressure.

10. Remove check plug. Oil must be to bottom of hole.

11. If necessary, add oil until oil flows out of oil level

check plug hole. (See Fuels and Lubricants chapter.)

12. Wrap threads of plug with sealing-type tape. Install

plug. Tighten plug to 49 Nm (36 lb-ft).

A--Fill Plug

B--Check Plug

13. Check second propel gearbox oil level.

C--Drain Plug

D--Horizontal Centerline

TX,75,DH5098

1908JUL962/2

CLEAN DUSTY PRIMARY ELEMENT

1. Tap element with the palm of your hand, NOT ON A

HARD SURFACE.

CAUTION: Prevent possible injury from flying

chips if compressed air is more than 210 kPa

(2.1 bar) (30 psi). Reduce compressed air to

less than 210 kPa (2.1 bar) (30 psi) when using

for cleaning purposes. Clear area of bystanders,

guard against flying chips, and wear personal

protection equipment including eye protection.

2. If this does not remove dust, use compressed air under

210 kPa (2.1 bar) (30 psi).

3. Direct air up and down the pleats from inside to

outside. Be careful not to make a break in the element.

03T,55,MM11

1918NOV921/1

14-9