TM 5-3805-280-10

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 230LCR/230LCRD

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

44

Weekly

Drain Fuel Tank Sump

*As Required

(1) Park machine on level surface. Rotate upper-

structure 90 for easier access.

(2) Remove fuel tank fill cap.

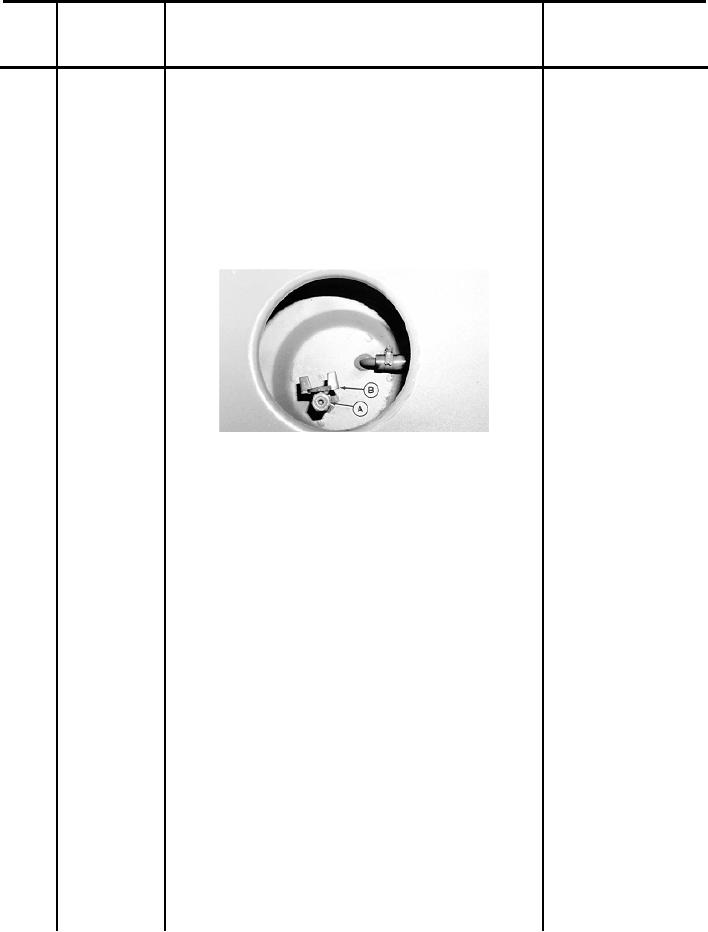

NOTE: Plug is installed in drain cock to

prevent vandalism.

(3) Remove plug (A) and open drain cock (B) for

several seconds to drain water and sediment

into a container. Dispose of waste properly.

Close drain cock.

(4) Install and tighten plug.

(5) Install fill cap.

45

Weekly

Check Arctic Starter Fuel Lines

Any Class III leak evident

(1) Visually check all fuel lines for leaks. Replace

damaged, worn, or corroded fuel lines.

NOTE: Items 46 through 49 are applicable to

Model 230LCRD only.

46

Weekly

Check Compressor Air Precleaner Dirt Dumps

(1) Squeeze the rubber valve (precleaner dirt

dump) on each air cleaner housing to ensure

that valves are not clogged.

47

Weekly

Check Compressor Fan Belts

Damaged or loose belts

48

Quarterly

Check All Compressor Hoses

Damaged hoses

A-20