TM 5-3805-280-24-1

Hydraulic System

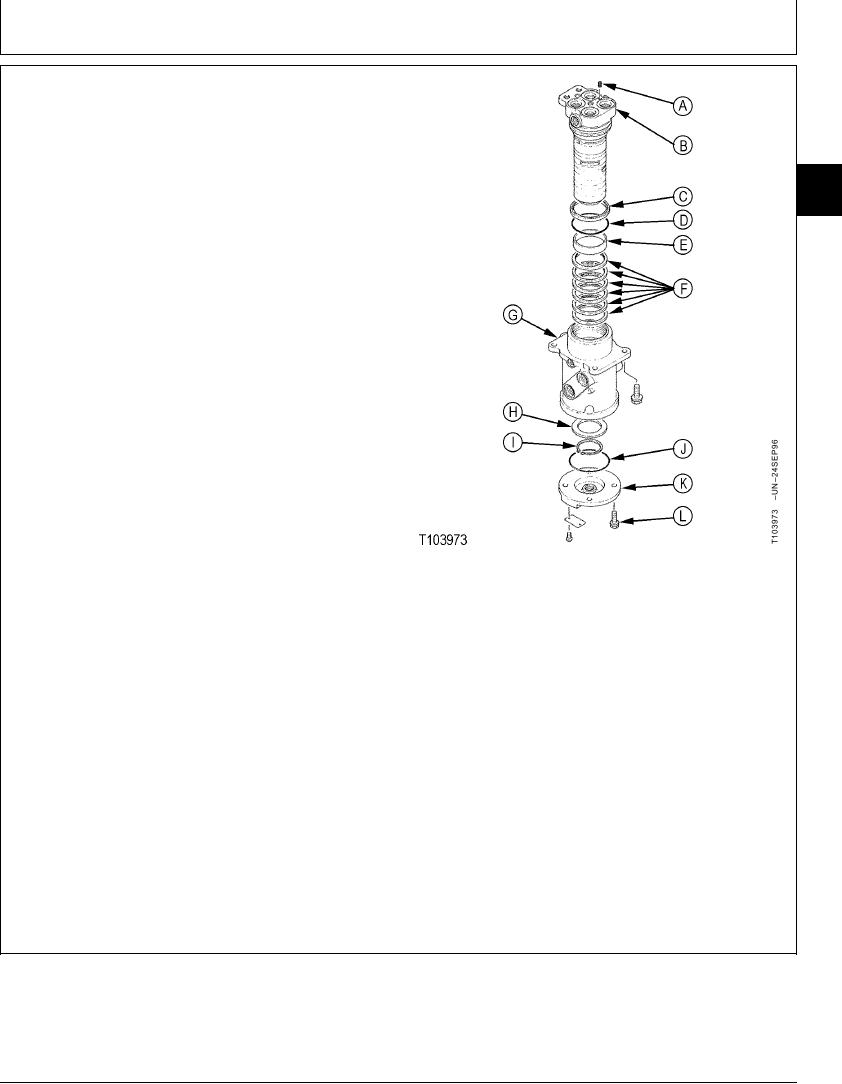

7. Inspect and repair as necessary. Keep hydraulic oil on

all disassembled parts.

8. Install bushing (E), O-ring (D), and seal (C) in housing

(G).

02

0260

9. Install oil seal rings (F) into housing (G)

37

IMPORTANT: Avoid damage to seals when installing

spindle into rotary manifold housing.

Clearance between spindle and housing

is approximately 0.1 mm (0.004 in.)

Spindle must not be tilted when

inserted into housing.

10. Carefully install spindle (B) into housing (G) so that

match marks align.

11. Install ring (H) with chamfered side down and snap

ring (I) with chamfered side down.)

12. Install O-ring (J) and cover (K) with cap screws (L).

Tighten cap screws.

Cover-to-Housing Cap Screw--Specification

Torque ............................................................................. 49 Nm (36 lb-ft)

A--Plug

B--Spindle

C--Dust Seal

D--O-Ring

E--Bushing

F--Oil Seal Ring (6 used)

G--Housing

H--Ring

I--Snap Ring

J--O-Ring

K--Cover

L--Cap Screw

TX,02,VV2723

1918SEP982/2

12-59