TM 5-3805-280-24-2

Cylinder Head and Valves

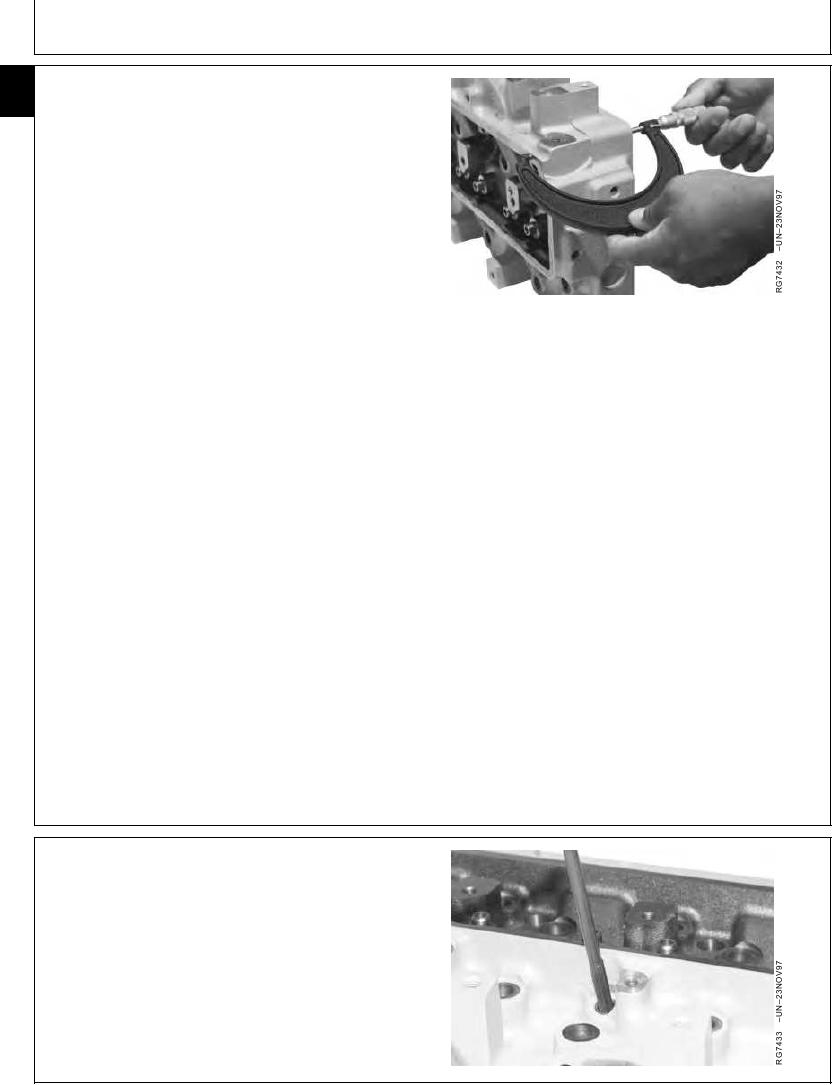

MEASURE CYLINDER HEAD THICKNESS

05

32

Measure head thickness from valve cover gasket

rail-to-combustion face.

If cylinder head thickness is less than minimum allowable

thickness, DO NOT attempt to resurface. Install a new

cylinder head.

When resurfacing cylinder head, remove ONLY what is

necessary to restore flatness.

Cylinder Head Thickness and Finish--Specification

New Cylinder Head Thickness .................................. 104.87--105.13 mm

(4.129--4.139 in.)

Minimum Acceptable Thickness............................. 104.24 mm (4.104 in.)

Combustion Face Surface Finish ............. 0.7--3.2 micrometers (31--125

(Surface Grind Only) (AA)

micro-in.)

Maximum Wave Depth .......................................... 0.012 mm (0.0005 in.)

Maximum Material Removal for ................................. 0.76 mm (0.030 in.)

Resurfacing

IMPORTANT: After resurfacing cylinder head, check

for flatness as described earlier. Also

check surface finish on combustion

face of head.

Measure and record valve recess in

cylinder head. (See CHECK VALVE

RECESS IN CYLINDER HEAD earlier in

this group.)

RG,05,DT7358 1911NOV971/1

CLEAN INJECTION NOZZLE BORES

IMPORTANT: Always turn the tool clockwise through

the bore, even when pulling back. This

will prevent premature wear on the tool.

Clean carbon deposits from nozzle bores with JDE39

Nozzle Bore Cleaning Tool. Blow debris from bore with

compressed air.

RG,05,DT7357 1911NOV971/1

13-90