TM 5-3805-280-24-2

Cylinder Head and Valves

05

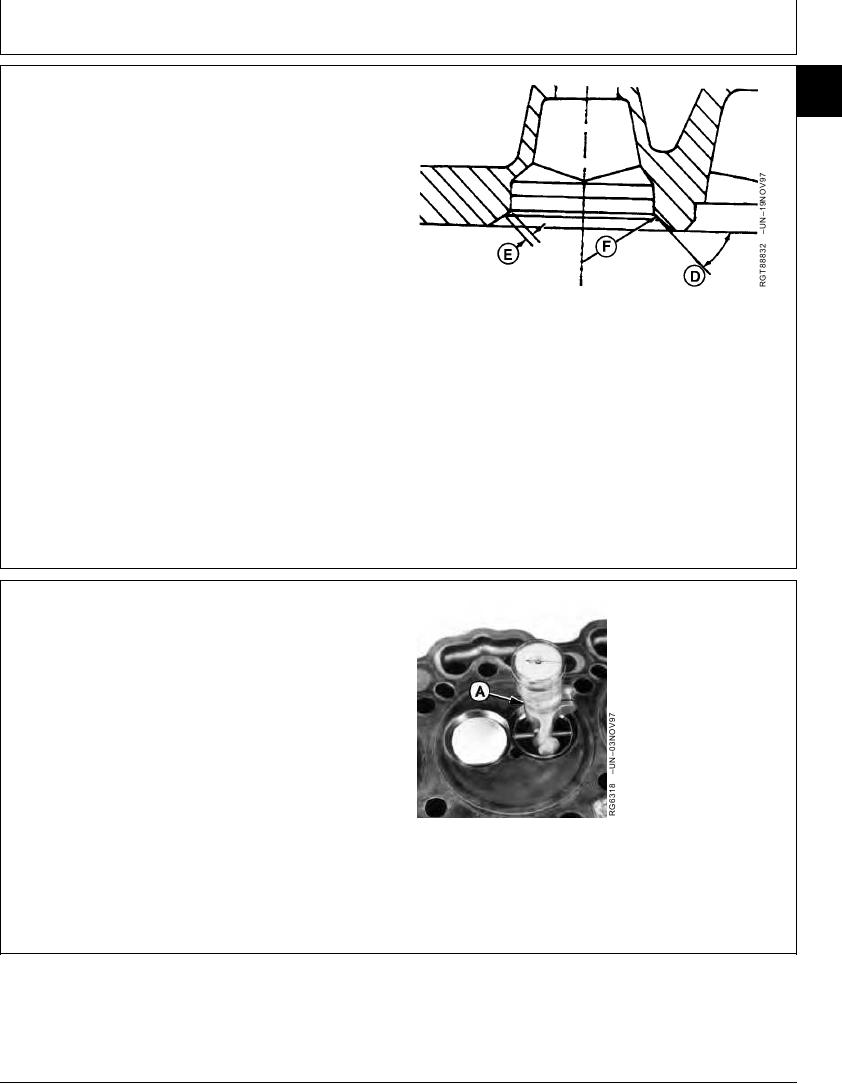

3. Using drill from JT05893 Heavy Duty Seat Grinder Set,

37

grind valve seats to the following specifications:

Valve Seat Grinding--Specification

Valve Seat Angle (D)............................................................................. 30

Valve Seat Width (E)........................... 1.50--2.00 mm (0.059--0.079 in.)

Maximum Valve Seat Runout (F)............................... 0.08 mm (0.003 in.)

4. Use a vernier caliper or scale to measure seat width. If

valve seat is too wide, reduce the width with a

narrowing stone.

NOTE: A narrowing stone will change the top angle of the

D--Valve Seat Angle

seat and reduce the outer diameter of the valve

E--Valve Seat Width

seating area. Varying the width changes the fine

F--Valve Seat Runout

contact between valve face and seat. If seat width

is too narrow, valve may burn or erode.

RG,05,DT7353 1911NOV973/4

5. If valve does not seat properly, use an eccentrimeter

(A) to check valve seat runout. Use a new or refaced

valve and blueing to check contact between valve seat

and face. If necessary, lap the valve onto its seat using

a lapping tool and lapping compound. Replace valves

and inserts as necessary.

6. Install new or refaced valve and check valve recess in

cylinder head after grinding. (See CHECK VALVE

RECESS IN CYLINDER HEAD earlier in this group.)

A--Eccentrimeter

RG,05,DT7353 1911NOV974/4

13-95