TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

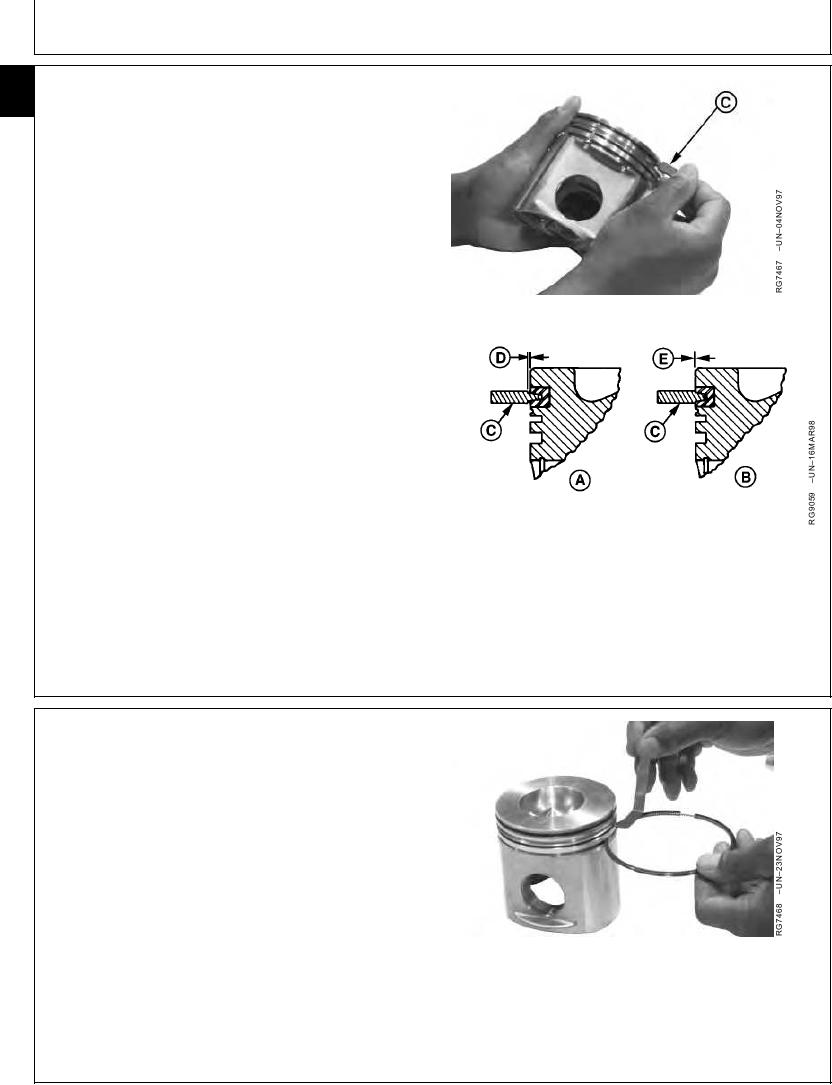

CHECK PISTON RING GROOVE WEAR

10

26

Pistons with tapered rods will use JDE62 Ring Groove

Wear Gauge and pistons with straight rods will use

JDG957 Ring Groove Wear Gauge.

1. Use the appropriate ring groove wear gauge (C) to

check wear of keystone ring groove (top groove).

Check grooves at several locations around the

circumference of piston.

Gauge shoulders should not contact ring land.

Clearance (D) between shoulders of tool and ring land

indicate ring groove is good.

If ring groove is worn, replace piston and liner as a

matched set. If ring groove is good, proceed to next

step.

A--Piston with Good Keystone Ring Groove

B--Piston with Worn Keystone Ring Groove

C--Ring Groove Wear Gauge

D--Clearance (Normal)

E--No Clearance (Replace)

RG,10,DT7414 1912NOV971/2

2. Check second and third ring grooves using a new

piston ring and a feeler gauge. Measure clearance at

several points. Compare measurements with

specifications.

Piston Ring-to-Groove Clearance--New Piston Ring (Second and

Third Ring Grooves)--Specification

Maximum Clearance................................................... 0.20 mm (0.008 in.)

3. Replace piston and liner (as a set) if clearance

exceeds specification.

RG,10,DT7414 1912NOV972/2

13-139