TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

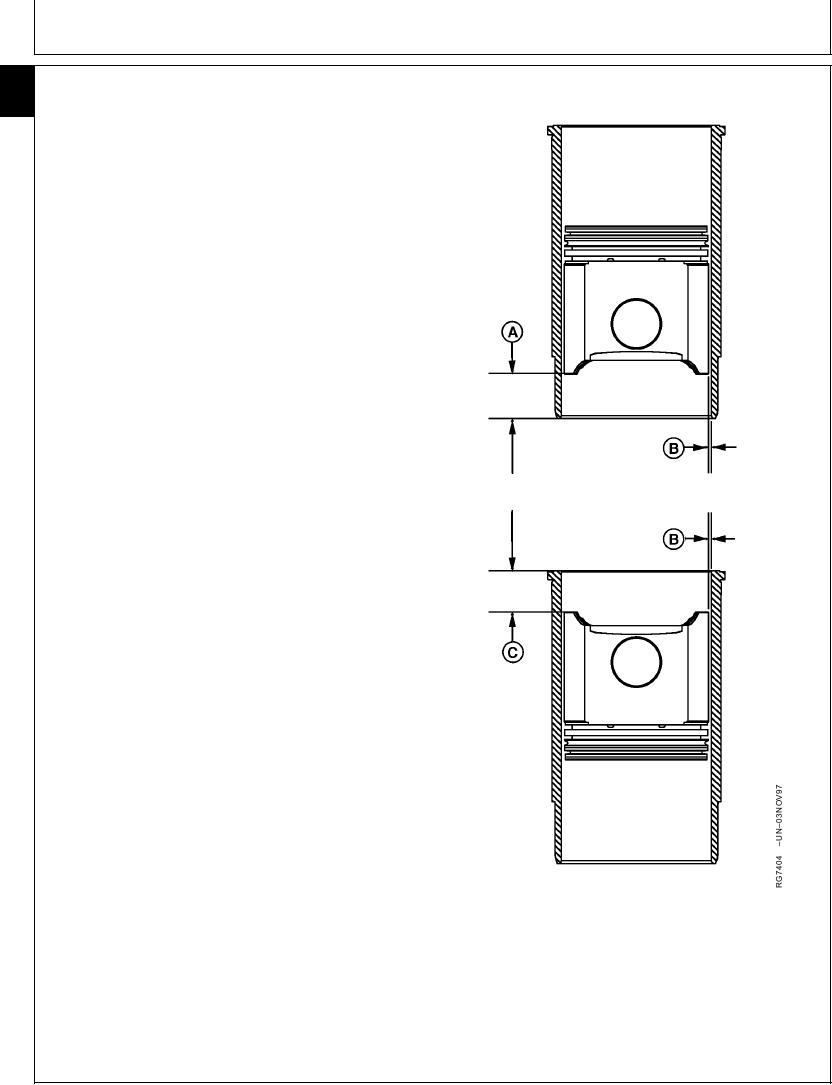

DETERMINE PISTON-TO-LINER CLEARANCE

10

28

1. Put piston (without rings) in matched liner with piston

"front" and liner "front"1 aligned. Move piston down until

bottom edge of piston skirt is 25.4 mm (1.00 in.) (A)

from bottom of liner. Use a feeler gauge to measure

clearance (B) between piston skirt and liner 90 to pin

bore. Record the measured clearance.

2. Turn piston 90 in liner. Measure clearance between

piston skirt and liner 90 to pin bore. Record the

clearance.

3. Put piston upside down in liner with piston "front" and

liner "front" aligned. Move piston so bottom edge of

piston skirt is 25.4 mm (1.00 in.) (C) below top of liner.

Measure clearance (B) between piston skirt and liner at

90 to pin bore. Record the clearance.

4. Turn piston 90 in liner. Measure clearance between

piston skirt and liner 90 to pin bore. Record the

clearance.

5. The difference between clearances in Steps 1 and 2 is

the amount liner is out-of-round at bottom of the liner.

6. The difference between clearances in Steps 3 and 4 is

the amount liner is out-of-round at top of the liner.

7. The difference between clearances in Steps 1 and 3 is

the amount liner is tapered.

Piston-to-Liner Clearance: (Measured at Bottom of Piston Skirt)

(Naturally Aspirated Engines)--Specification

Clearance ............................................ 0.08--0.14 mm (0.003--0.005 in.)

Piston-to-Liner Clearance: (Measured at Bottom of Piston Skirt)

(Turbocharged Engines)--Specification

Clearance ............................................ 0.08--0.15 mm (0.003--0.006 in.)

Cylinder Liner Out-Of-Round (Top or Bottom)--Specification

Maximum Out-of-Round ............................................. 0.05 mm (0.002 in.)

A--25.4 mm (1.00 in.)

B--Skirt-to-Liner Clearance

C--25.4 mm (1.00 in.)

1

As marked during liner removal from engine.

Continued on next page

RG,10,DT7411 1912NOV971/2

13-141