TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

10

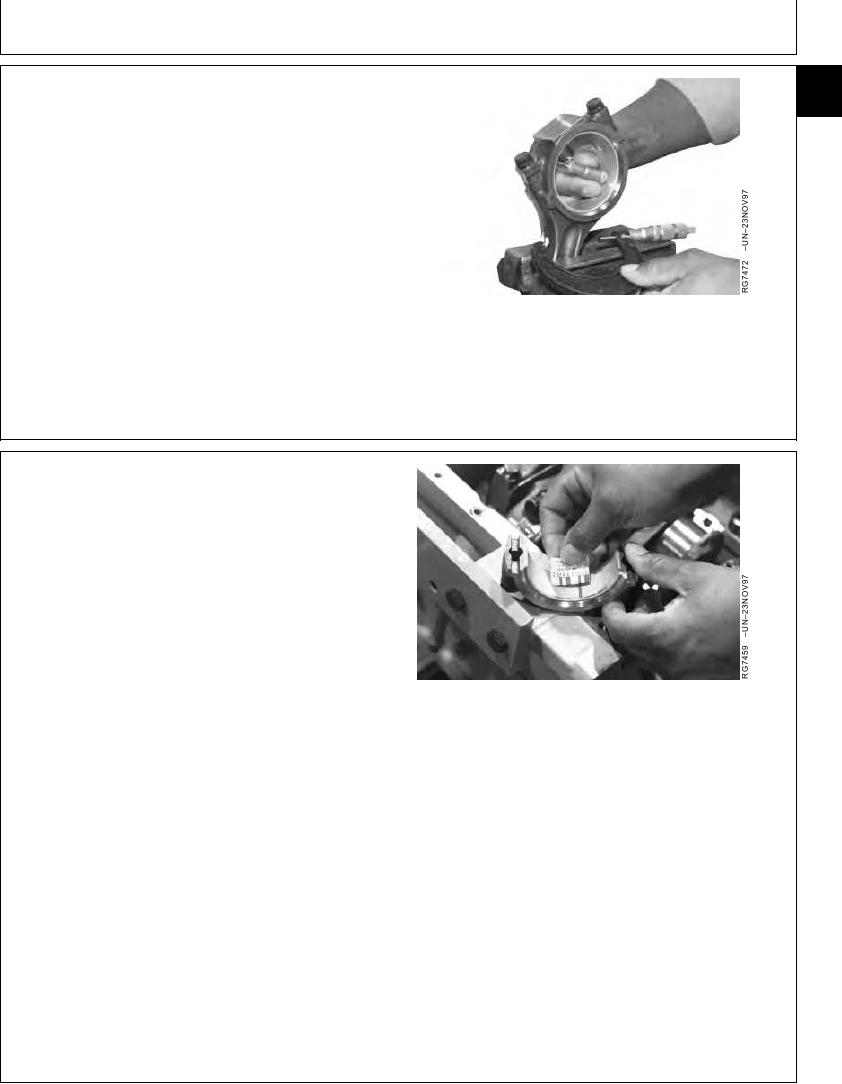

4. Measure assembled rod bearing ID.

31

Assembled Rod Bearing--Specification

ID ............................................................................... 77.876--77.927 mm

(3.0659--3.0679 in.)

5. Subtract crankshaft journal OD from rod bearing ID to

determine oil clearance. Replace bearings if oil

clearance is out of specification.

Connecting Rod Bearing-to-Journal (New Parts)--Specification

Oil Clearance................................................................. 0.050--0.127 mm

(0.0020--0.0050 in.)

Wear Limit .............................................................. 0.152 mm (0.0600 in.)

RG,10,DT7409 1912NOV972/2

INSPECT AND MEASURE CONNECTING ROD

BEARINGS (ROD AND CRANKSHAFT IN

ENGINE)

IMPORTANT: Use hand wrenches. Pneumatic

wrenches may cause thread damage.

NOTE: Use PLASTIGAGE as directed by manufacturer.

PLASTIGAGE will determine oil clearance, but

will not indicate condition of either surface.

1. Remove rod cap. Place a piece of PLASTIGAGE in

center of bearing. Install rod cap using OLD cap

screws. Tighten cap screws to 58 Nm (43 lb-ft).

Tighten cap screw an additional 90--100. (See

TORQUE-TURN CONNECTING ROD CAP SCREWS

later in this group.)

2. Remove rod cap. Compare width of PLASTIGAGE

with scale provided on package to determine

clearance. Replace bearings if oil clearance is out of

specification.

PLASTIGAGE is a registered trademark of the DANA Corp.

DPSG,OUO1004,52

1916APR981/1

13-144