TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

INSPECT PISTON PINS AND BUSHINGS

10

34

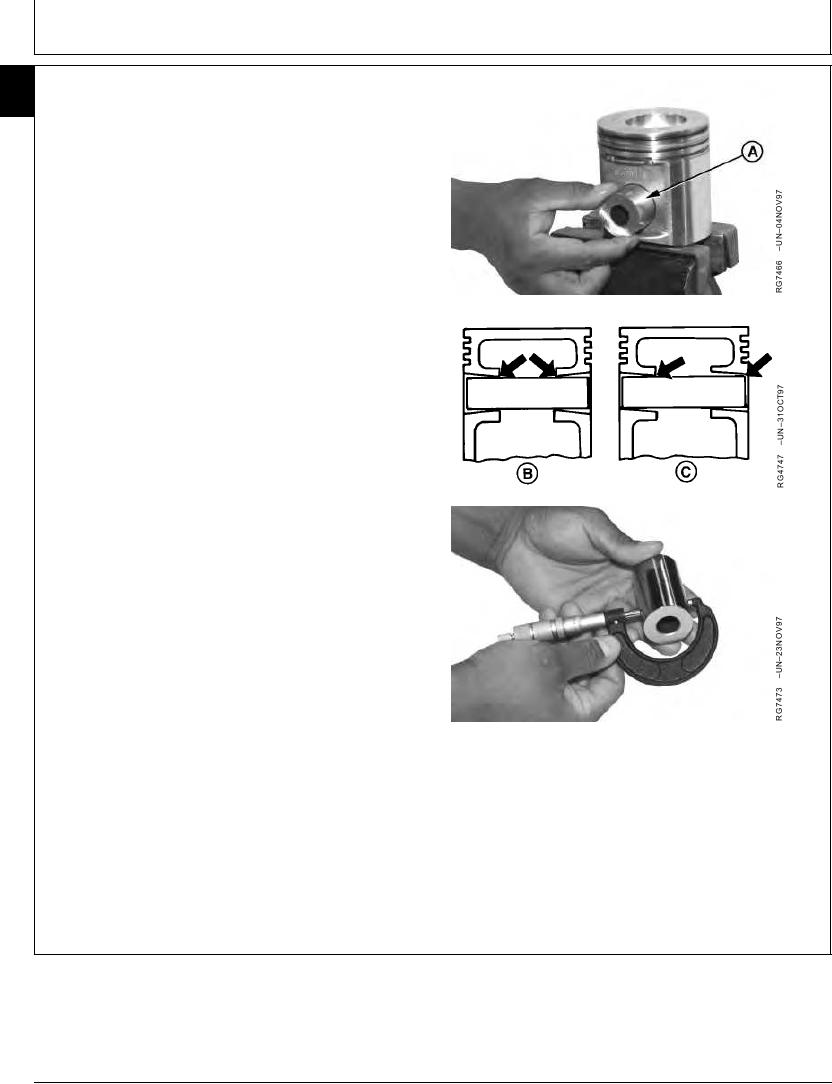

1. Visually inspect piston pin. Pin must be in good

condition with no visible wear.

IMPORTANT: Do not attempt to polish or refinish

piston pin. Pin has a highly polished

surface.

2. Dip piston pin in clean engine oil.

3. Install pin (A) through piston. Pin should pass through

piston using only light thumb pressure.

4. Insert pin from both sides. If pin enters freely, but binds

in the center, the bore could be tapered (B).

5. Insert pin to check for bore alignment (C). Pin should

not "click" or need to be forced into bore on opposite

side.

6. Measure piston pin OD. Replace if not within

specification.

Piston Pin (Small)--Specification

OD ............................................................................. 34.920--34.930 mm

(1.3748--1.3752 in.)

Wear Limit ............................................................ 34.907 mm (1.3743 in.)

Piston Pin (Large)--Specification

OD ............................................................................. 41.270--41.280 mm

(1.6248--1.6252 in.)

Wear Limit ............................................................ 41.257 mm (1.6243 in.)

Piston Pin--Specification

Length.................................................... 71.51--72.11 mm (2.815--2.839

A--Piston Pin

in.)

B--Tapered Bore

C--Bore Alignment

Continued on next page

RG,10,DT7407 1912NOV971/2

13-147