TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

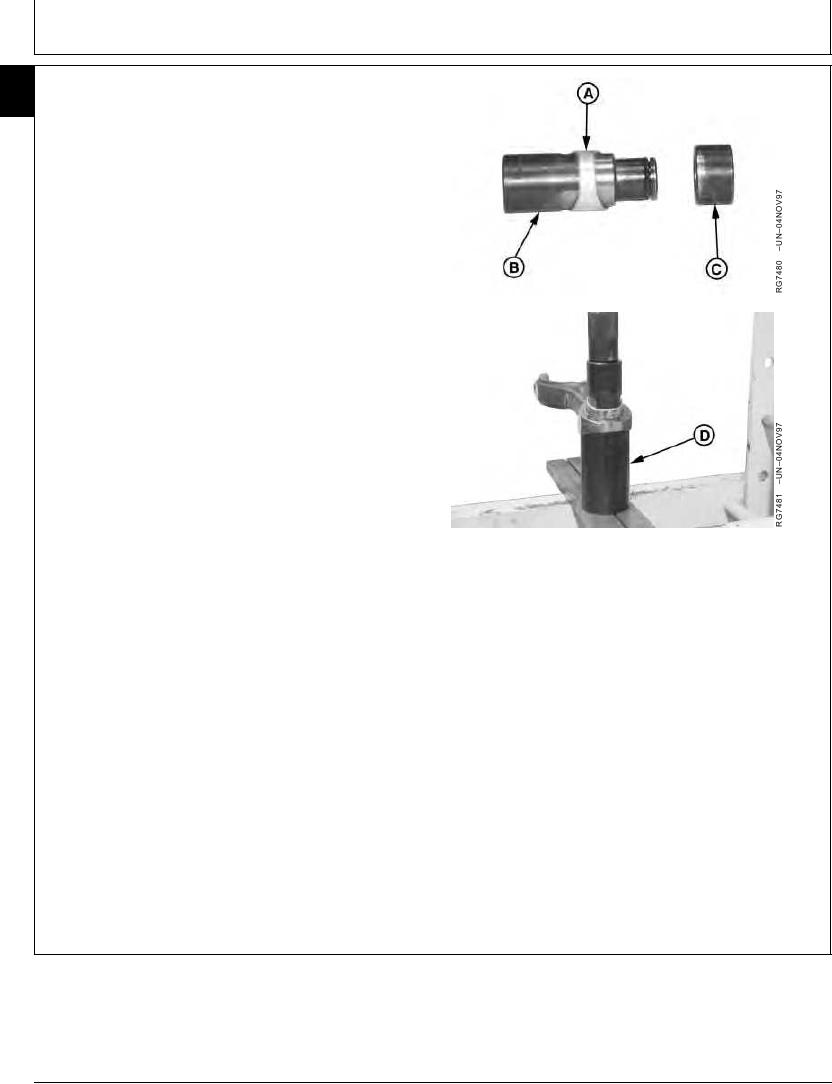

INSTALL PISTON PIN BUSHING IN

10

38

CONNECTING ROD

Carefully file a slight chamfer on edge of rod pin bore.

Remove any burrs or sharp edges from edge of bushing

bore.

NOTE: Tapered pin-end rods do not have a lubrication

hole in the rod or bushing.

INSTALLING PISTON PIN BUSHING IN TAPERED

PIN-END ROD

1. Slide bushing (A) onto JDG953-1 Driver (B) and install

JDG738-2 Installer Pilot (C) onto O-ring end of driver.

Apply clean engine oil or grease to O.D. of new

bushing, O.D. of pilot ring, and I.D. of rod pin bore.

2. Insert driver into rod pin bore so pilot ring pilots in rod

bore, and bushing taper aligns with taper on driver

flange.

3. Install JDG953-2 Receiver Cup (D) onto the opposite

side of rod.

4. Press bushing into rod bore until edge of bushing is

A--Piston Pin Bushing

flush or just slightly below rod face.

B--JDG953-1 Driver

C--JDG738-2 Installer Pilot

5. If necessary, have the new bushing reamed by a

D--JDG953-3 Receiver Cup

specialized machine shop to obtain specified oil

clearance with piston pin.

Connecting Rod Pin-to-Bushing (Tapered Pin-End)--Specification

Oil Clearance................................................................. 0.020--0.056 mm

(0.0008--0.0022 in.)

Continued on next page

RG,10,DT7404 1912NOV971/2

13-151