TM 5-3805-280-24-2

Cylinder Block, Liners, Pistons and Rods

10

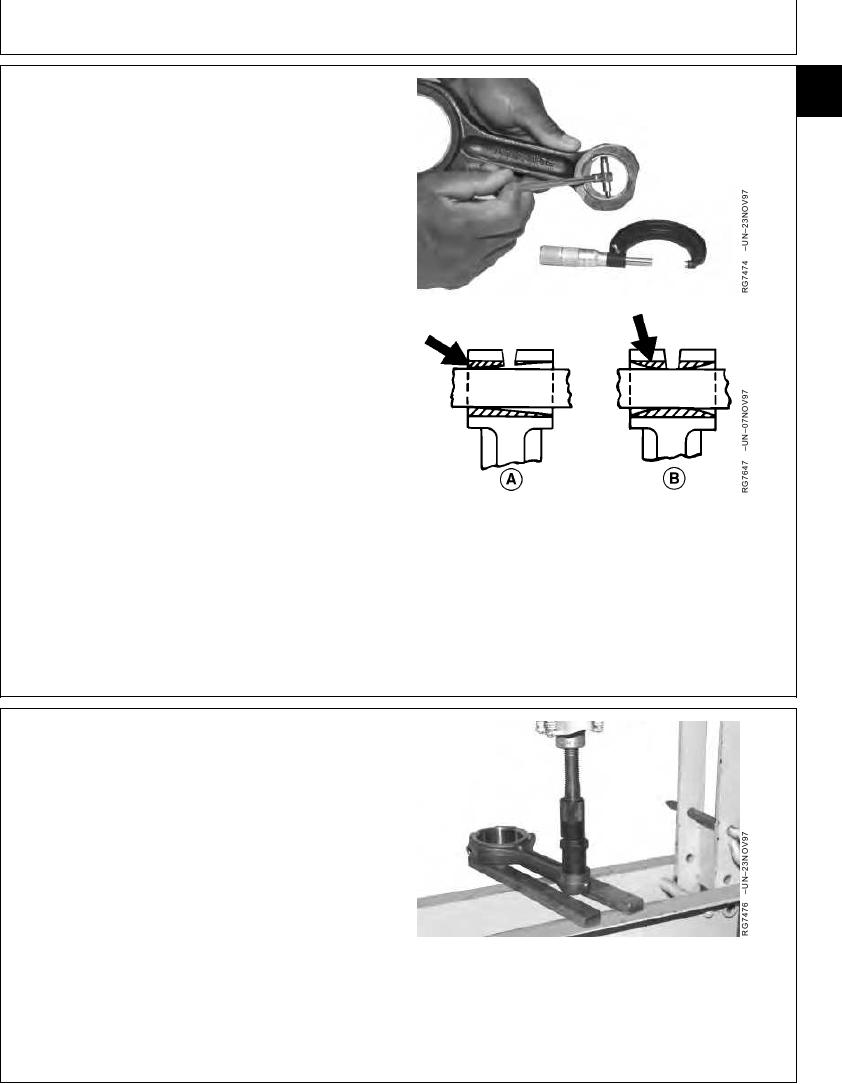

NOTE: Straight-end rods have an oil hole; tapered-end

35

rods do not.

7. Lubrication hole must be open.

8. Measure pin bushing ID and compare to pin OD to

determine oil clearance.

Piston Pin Bushing Installed (Small Pin)--Specification

ID ............................................................................... 34.950--34.976 mm

(1.3760--1.3770 in.)

Wear Limit ............................................................ 35.026 mm (1.3790 in.)

Piston Pin Bushing Installed (Large Pin)--Specification

ID ............................................................................... 41.300--41.326 mm

(1.6260--1.6270 in.)

Wear Limit ............................................................ 41.376 mm (1.6290 in.)

Piston Pin-to-Bushing--Specification

Oil Clearance................................................................. 0.020--0.056 mm

(0.0008--0.0022 in.)

Wear Limit .............................................................. 0.102 mm (0.0040 in.)

9. Insert pin from either side of rod bushing. If pin is free

A--Tapered Bore

on one end, but tight on the other, the bore could be

B--Bell Mouthed Bore

tapered (A). If pin enters freely from both sides, but is

tight in the center, bore is bell mouthed (B).

RG,10,DT7407 1912NOV972/2

REMOVE PISTON PIN BUSHING

REMOVING PISTON PIN BUSHING ON STRAIGHT

PIN-END ROD

Use JD286 Driver for 41 mm (1.6 in.) pin, or JDE88 Driver

for 35 mm (1.3 in.) pin to remove bushing.

Straight Pin-End Rod

Continued on next page

RG,10,DT7406 1912NOV971/2

13-148