TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

15

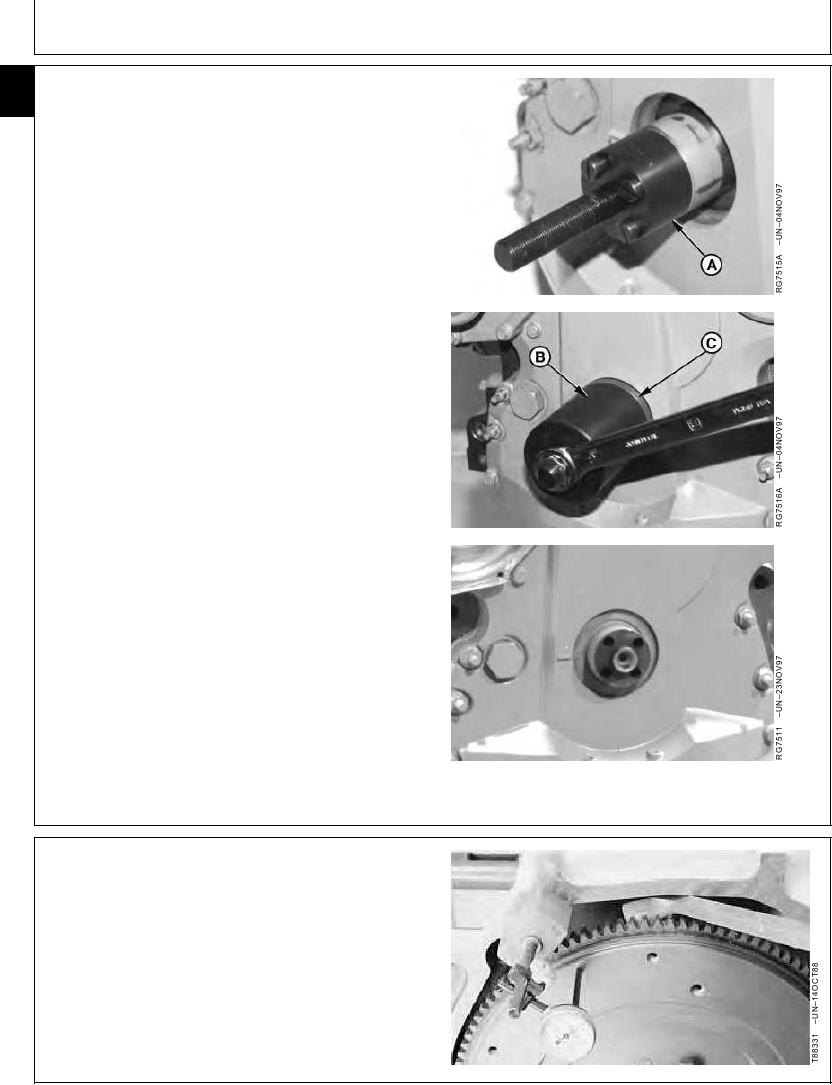

INSTALL FRONT CRANKSHAFT OIL SEAL:

20

1. Inspect and clean seal bore in timing gear cover.

Check for nicks or burrs. Use a medium-grit emery

cloth to smooth rough areas.

IMPORTANT: To assure proper sealing, the OD of the

crankshaft and wear sleeve MUST BE

cleaned with Brake Kleen, Ignition

Cleaner, or equivalent and dry prior to

installing seal (C).

2. Slide JDG954-2 Adapter (A) on nose of crankshaft and

tighten cap screws.

IMPORTANT: DO NOT allow oil to contact coating on

OD of seal.

3. Apply a light coating of clean engine oil to lips of seal

and position seal on crankshaft flange. (The

spring-loaded side of seal goes into timing gear cover

first.)

4. Place JDG954-1 Installer (B) over adapter. Tighten

screw until driver bottoms on nose of crankshaft.

5. Install vibration damper/pulley or pulley on crankshaft

as previously instructed in this group.

6. Install poly-vee belts.

RG,15,DT7455 1914NOV9710/10

CHECK CRANKSHAFT END PLAY

Measure end play prior to removing crankshaft to

determine condition of thrust bearings.

1. Position dial indicator on contact face of flywheel, on

front crankshaft nose, on damper, or front pulley

assembly if installed.

Continued on next page

RG,15,DT7454 1914NOV971/3

13-198