TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

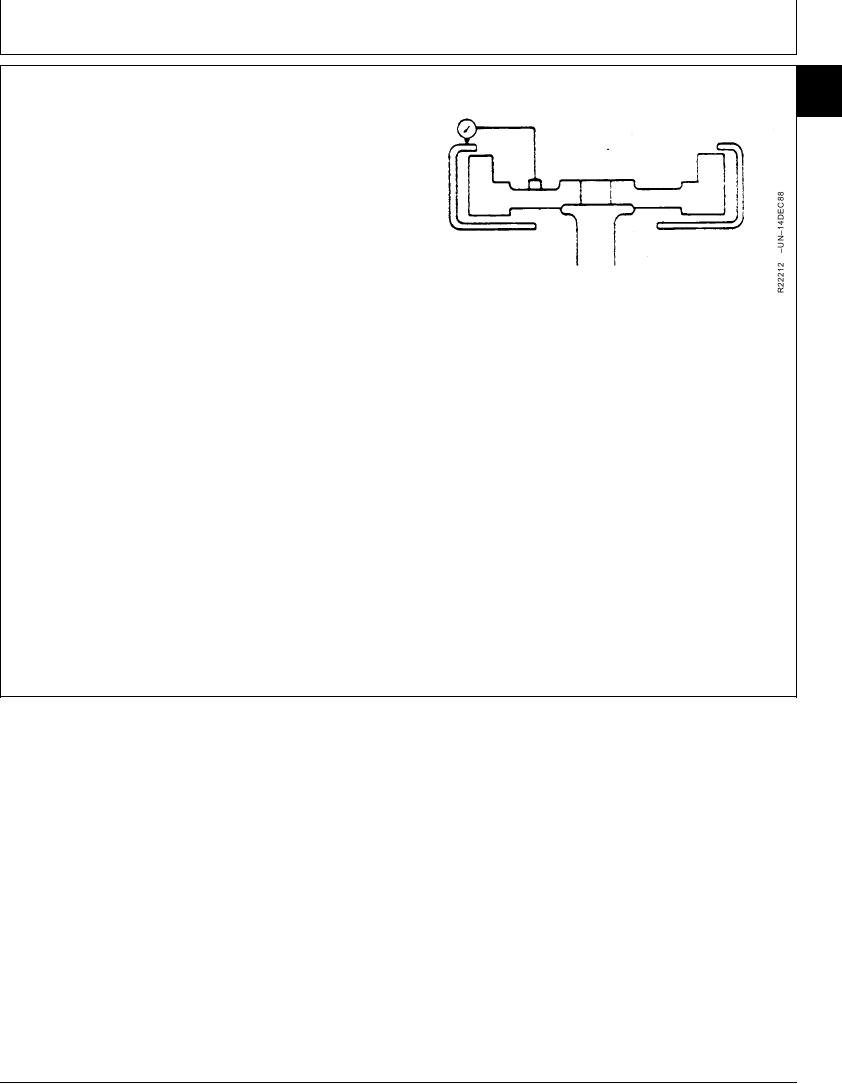

CHECK FLYWHEEL HOUSING FACE

15

23

RUNOUT

1. Mount dial indicator on flywheel. Set pointer to contact

PTO mounting surface on flywheel housing and at right

angles. Pointer should not contact holes in flywheel

housing.

2. Preload indicator tip. Set dial indicator to 0.0 mm (in.).

IMPORTANT: Maintain constant end pressure on

crankshaft to hold shaft against thrust

bearing when measuring flywheel

housing face runout.

3. Rotate flywheel by turning crankshaft. Read total dial

indicator movement. It should not exceed

specifications.

Flywheel Housing--Specification

Maximum Face Runou (12......................................... 0.30 mm (0.012 in.)

O'Clock)

Maximum Face Runout (3 and 9 ............................... 0.25 mm (0.010 in.)

O'Clock)

4. If runout exceeds specifications, resurface flywheel

housing face or replace housing as necessary.

DPSG,OUO1004,214

1909JUL981/1

13-201