TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

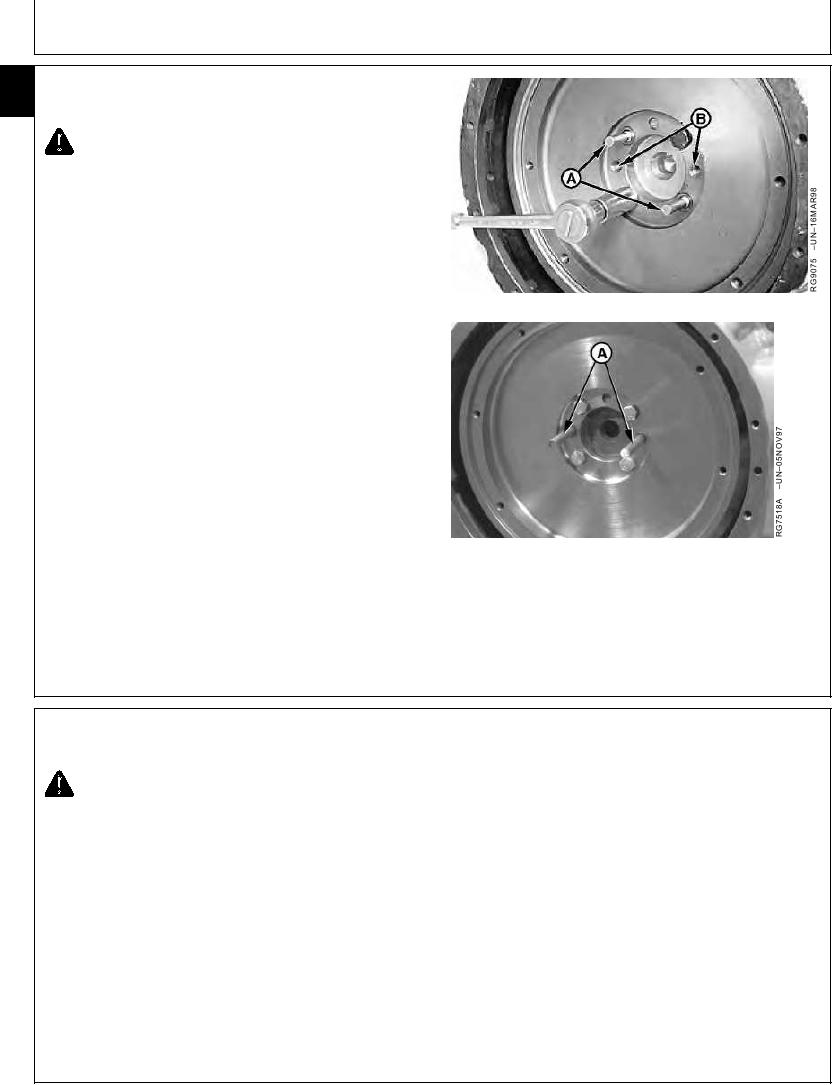

REMOVE FLYWHEEL

15

24

CAUTION: Flywheel is heavy. Plan a proper

lifting procedure to avoid personal injury.

1. Remove two cap screws and install guide studs (A) in

their place. Remove the remaining cap screws.

2. On flywheels secured with four cap screws: Install

two cap screws in threaded jack screw holes (B).

Tighten cap screws evenly to remove flywheel.

Four Cap Screw Flywheel

3. On flywheels secured with six cap screws: Pry

flywheel off of crankshaft.

NOTE: If flywheel to housing clearance will not allow use

of a pry bar, install a punch through timing pin

hole and tap on flywheel face to drive from

crankshaft.

Six Cap Screw Flywheel

A--Guide Studs

B--Jack Screw Holes

RG,15,DT7452 1914NOV971/1

REPLACE FLYWHEEL RING GEAR

CAUTION: Oil fumes or oil can ignite above

193C (380F). Use a thermometer and do not

exceed 182C (360F). Do not allow a flame or

heating element to be in direct contact with the

oil. Heat the oil in a well ventilated area. Plan a

safe handling procedure to avoid burns.

1. Place the flywheel on a solid flat surface.

Continued on next page

RG,15,DT7451 1914NOV971/3

13-202