TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

15

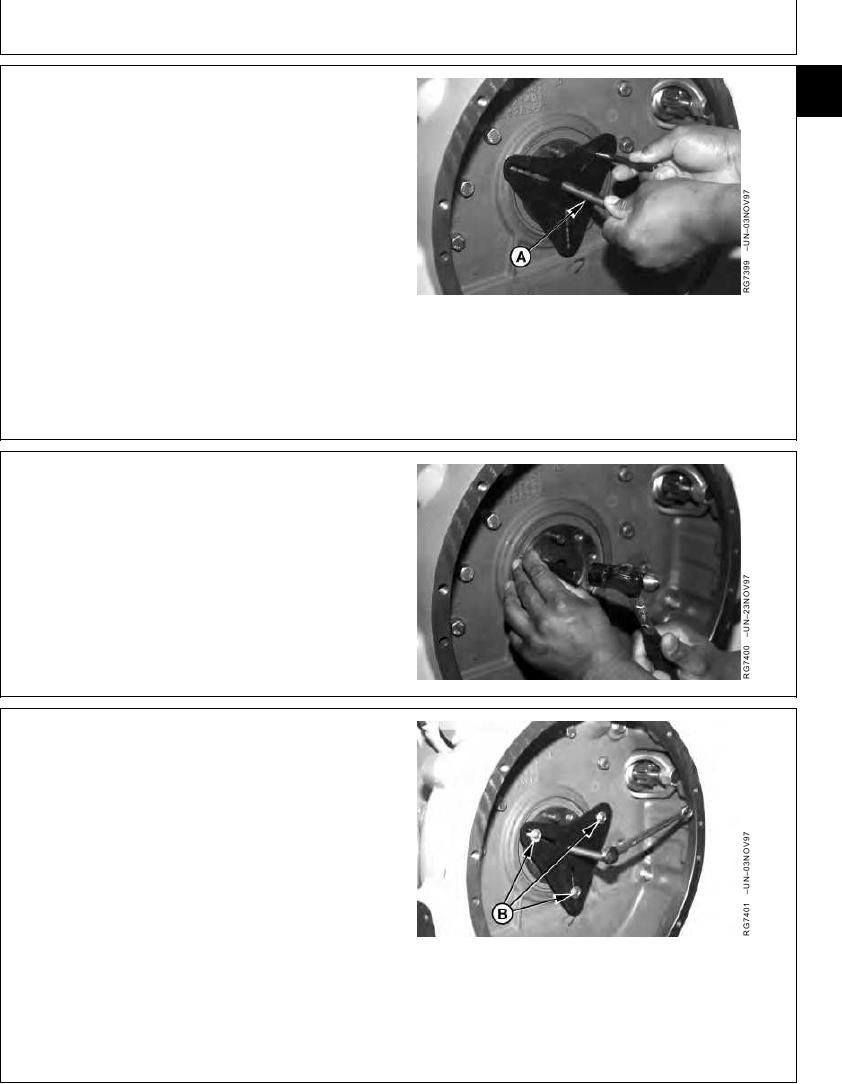

REMOVE OIL SEAL/WEAR SLEEVE USING JDG698

29

1. Adjust forcing screw (A) on JDG698 Seal and Wear

Sleeve Remover and position screw so it centers tool

on crankshaft flange.

2. Use the slots in JDG698 Remover as a template, mark

three locations on seal casing where screws should be

installed for removal purposes. Remove tool from

crankshaft flange.

A--Forcing Screw

RG,15,DT7447 1914NOV972/9

IMPORTANT: Holes must be drilled at outer edge of

seal case. Screws will pull seal against

wear ring, thereby removing both

pieces.

3. Drill a 3/16 in. hole through wear sleeve lip and seal

casing at the three marked locations.

4. Position JDG698 Remover on end of crankshaft.

RG,15,DT7447 1914NOV973/9

5. Install three 2-1/2 in. (approximate) sheet metal screws

with washers (B) into slots of removal tool and thread

screws into holes in seal casing. Evenly tighten screws

until plate is flush with rear face of crankshaft.

6. Tighten forcing screw (plate should pull evenly against

the three screws) until seal and wear sleeve assembly

is removed from engine.

B--Sheet Metal Screws

Continued on next page

RG,15,DT7447 1914NOV974/9

13-207