TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

INSPECT CRANKSHAFT

15

41

NOTE: If vibration damper damage was discovered

during teardown, it is recommended that the

crankshaft be magna-fluxed. This will verify

whether of not it has microscopic cracks or

fissures. See INSPECT VIBRATION DAMPER

earlier in this group.

1. Thoroughly clean crankshaft. Clear restrictions from all

oil passages.

IMPORTANT: Small cracks may not be visible to the

eye. Use a method such as the

Fluorescent Magnetic Particle Method.

This method magnetizes the crank,

employs magnetic particles which are

fluorescent and glow under "black

light". The crankshaft must be

de-magnetized after inspection.

2. Inspect crankshaft for signs of load stress, cracks,

scoring, or journal scratches. Replace crankshaft if

cracks are found.

3. Check each journal for evidence of excessive

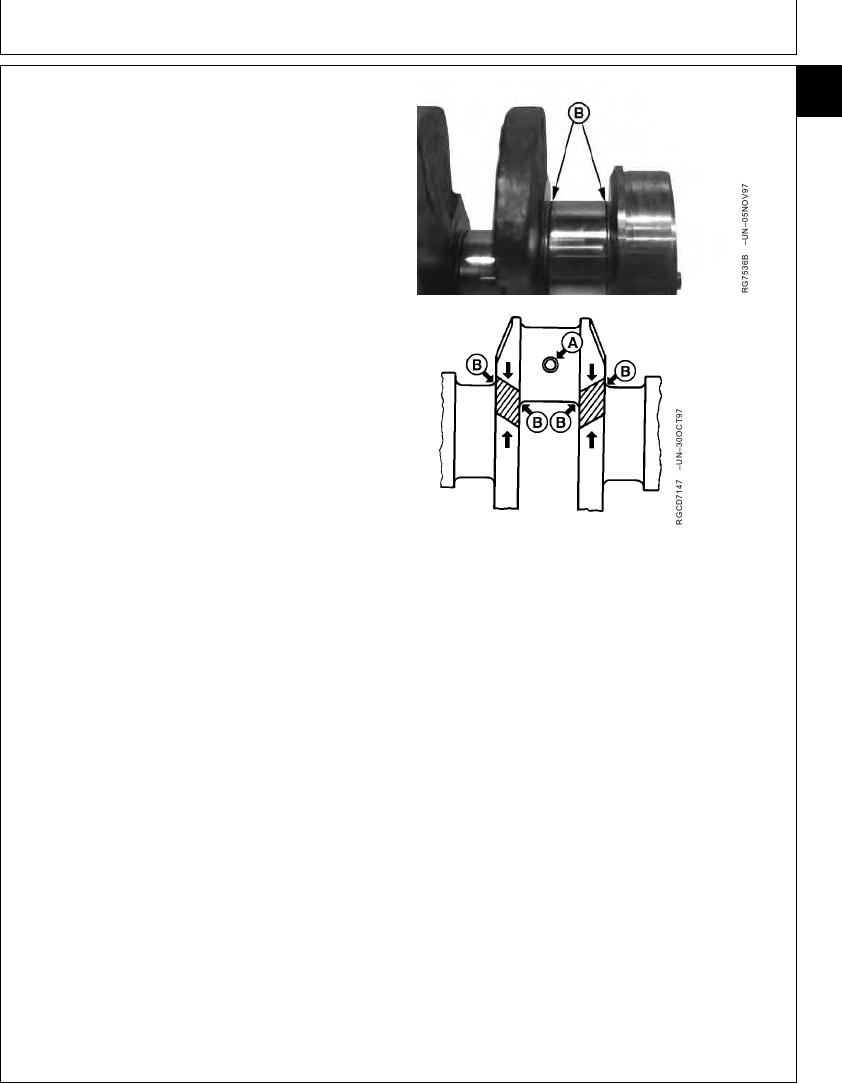

A--Rod Journal Holes

overheating or discoloration. If either condition exists,

B--Journal Fillets

replace crankshaft since heat treatment has probably

been destroyed.

4. Inspect front crankshaft gear for cracks, chipped teeth,

or excess wear. Replace gear as required.

5. Inspect the keyway for evidence of cracks or wear.

Replace crankshaft as necessary.

6. Carefully inspect the rear hub of the crankshaft in the

area of the wear sleeve contact surface for evidence of

a rough or grooved condition. Any imperfections in this

area will result in oil leakage. Slight ridges may be

cleaned up with emery cloth or crocus cloth.

7. Carefully check the crankshaft for cracks in the area of

rod journal holes (A) and at journal fillets (B). Replace

crankshaft if any cracks are found.

RG,15,DT7440 1914NOV971/1

13-219