TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

CRANKSHAFT GRINDING GUIDELINES

15

44

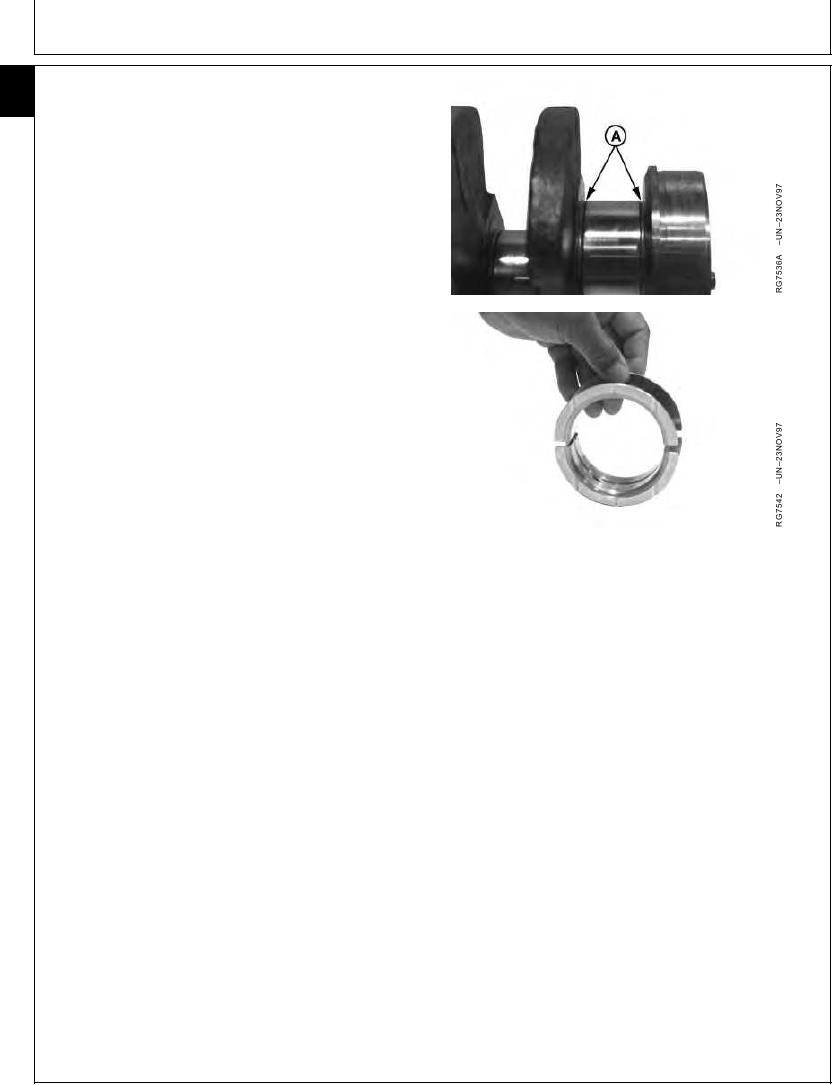

IMPORTANT: Crankshaft grinding should be done

ONLY by experienced personnel on

equipment capable of maintaining

crankshaft size and finish

specifications. Undercut and rolled

fillets (A) have taken the place of

ground (tangential) fillets. DO NOT

grind within this undercut area when

undersize bearings are used.

Crankshafts have micro-finished journal surfaces.

IMPORTANT: If undersize bearings are installed,

recheck bearing-to-journal clearance. If

oil clearance is not within

specifications, premature wear of

bearings and journals will result.

If the crankshaft is to be reground, use the following

recommended guidelines:

1. Compare the crankshaft journal measurements taken

during inspection and determine the size which the

journals are to be reground.

A--Fillets

2. Grind all main journals or all connecting rod journals to

the same required size.

IMPORTANT: Care must be taken to avoid localized

heating which often produces grinding

cracks. Use coolant generously to cool

the crankshaft while grinding. DO NOT

crowd the grinding wheel into the work.

Grind crankshaft with journals turning

counterclockwise, as viewed from the

front end of the crankshaft. Lap or

polish journals in opposite direction of

grinding.

3. Polish or lap the ground surfaces to the specified finish

to prevent excessive wear of the journals.

Continued on next page

RG,15,DT7437 1914NOV971/2

13-222