TM 5-3805-280-24-2

Crankshaft, Main Bearings and Flywheel

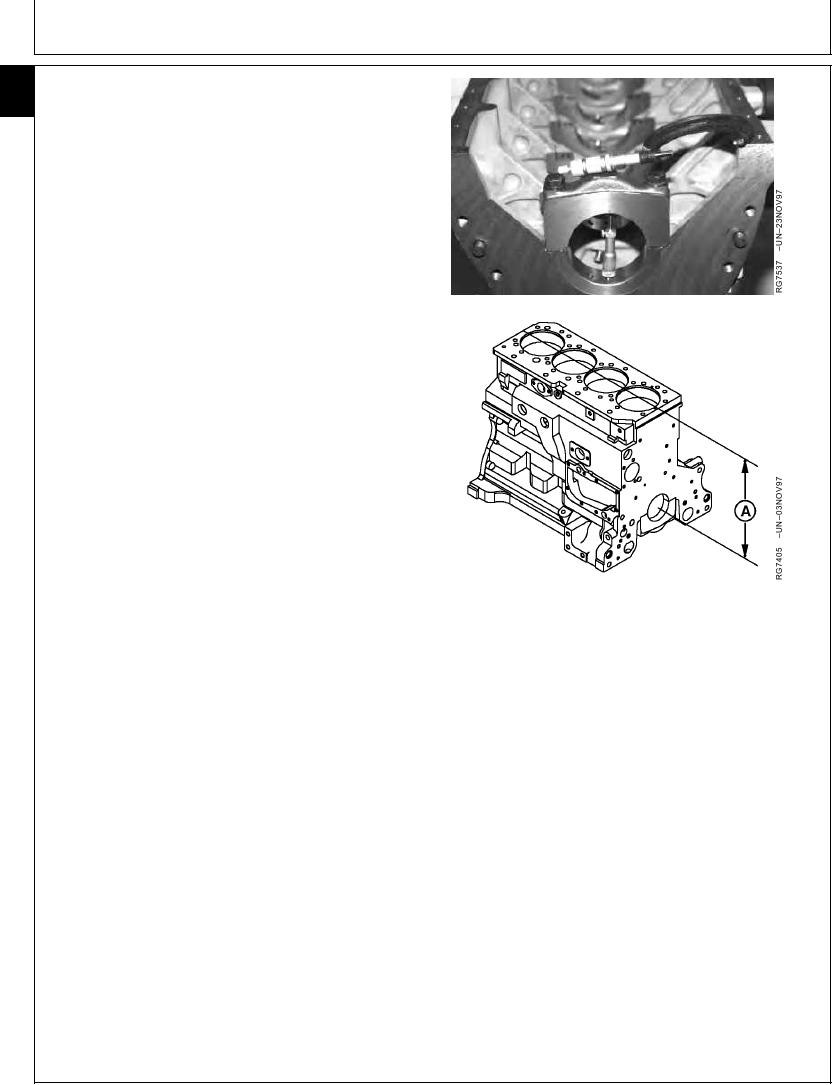

MEASURE ASSEMBLED ID OF MAIN

15

46

BEARING CAPS

1. Remove bearing inserts from caps and cylinder block.

Keep inserts in correct order if they are to be reused.

2. Clean and inspect caps for damage. Small burrs or

nicks on flat surfaces may be removed with a file. Use

a medium-grit polishing cloth to dress curved bearing

surfaces.

3. Install bearing caps (without bearings) in cylinder block.

Tighten cap screws to 135 Nm (100 lb-ft).

4. Measure ID of bearing cap bores.

Crankshaft Main Bearing Bore (Without Bearings)--Specification

ID ............................................................................... 84.455--84.481 mm

(3.3250--3.3260 in.)

Crankshaft Main Bearing Bore Centerline-to-Top

Deck--Specification

Distance................................................................. 337.896--337.972 mm

(13.3029--13.3059 in.)

IMPORTANT: When cylinder block is line bored,

dimension (A) from centerline of main

bearing bore to cylinder block top deck

will be changed. Piston may contact

A--Top Deck-to-Centerline Bearing Bore

cylinder head if this dimension is less

than specified above. Main bearing line

boring should be done ONLY by

experienced personnel on equipment

capable of maintaining bore

specifications.

5. If bearing caps are damaged or bore is not within

specification, install a new cap and line bore to

specified size. (See MEASURE MAIN BEARING ID

AND CRANKSHAFT JOURNAL OD, earlier in this

group.)

NOTE: Replacement bearing caps are supplied with

unfinished bearing bore.

RG,15,DT7436 1914NOV971/1

13-224