TM 5-3805-280-24-2

Fuel System

35

IMPORTANT: Do NOT overtighten cap screws on

40

pump cover plate to avoid damage to

O-ring.

8. Install access cover plate using a new O-ring, if

needed. Apply LOCTITE 242 (TY9370) to cap screw

threads and tighten to specifications.

Rotary Injection Pump Front Access Plate Cap Screws--

Specification

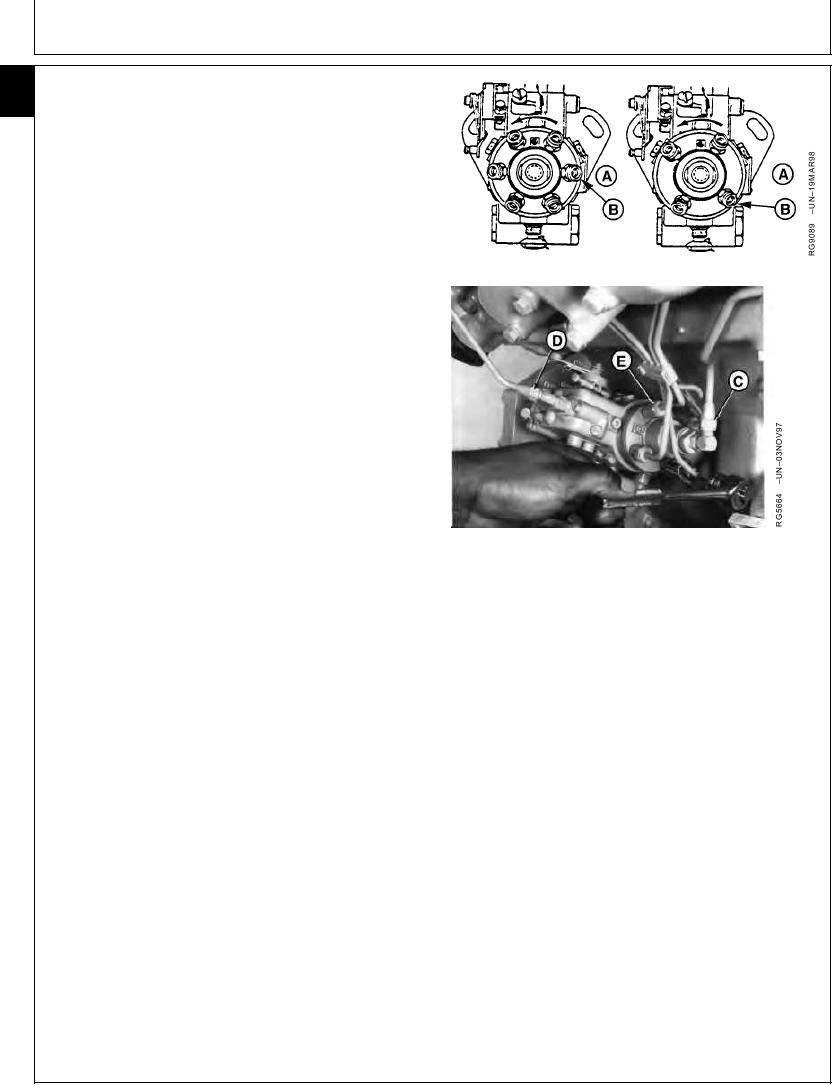

6-Cyl Engine (Left) 4-Cyl Engine (Right)

Torque .............................................................. 2 Nm (1.7 lb-ft) (20 lb-in.)

9. Align timing mark on pump flange with timing mark on

front plate.

10. Tighten three hex nuts securing the pump to the front

plate to specifications.

Rotary Injection Pump Mounting Nuts--Specification

Torque ............................................................................. 27 Nm (20 lb-ft)

11. Connect injection pump pressure lines (E). Beginning

with outlet (B) and continue around the pump head in

counterclockwise direction, attaching lines in same

order as engine firing (1-5-3-6-2-4 on 6-cylinder

engines and 1-3-4-2 on 4-cylinder engines).

A--Engine Block Side

B--Outlet Connection to No.1 Cylinder

C--Fuel Supply Line

12. Tighten fuel delivery (pressure) lines at pump to

D--Fuel Return Line

specifications, using a suitable 17 mm deep-well

E--Fuel Delivery (Pressure) Lines

socket.

Fuel Injection Pump Delivery Lines (At Pump)--Specification

Torque ............................................................................. 27 Nm (20 lb-ft)

IMPORTANT: ALWAYS use a backup wrench when

loosening or tightening fuel delivery

lines at fuel injection pump, so that the

pump discharge fittings are not altered.

This prevents possible internal pump

damage.

13. Connect fuel supply line (C) and fuel return line (D).

LOCTITE is a registered trademark of Loctite Corp.

Continued on next page

RG,35,JW7606

1920NOV973/4

13-419