TM 5-3805-280-24-2

Fuel System Operation and Tests

115

IMPORTANT: Many machines have hydraulic pumps

21

that have adequate flow to load engine

well below rated load rpm. Some

equipment may need to be driven in

high gear or pull a load to bring engine

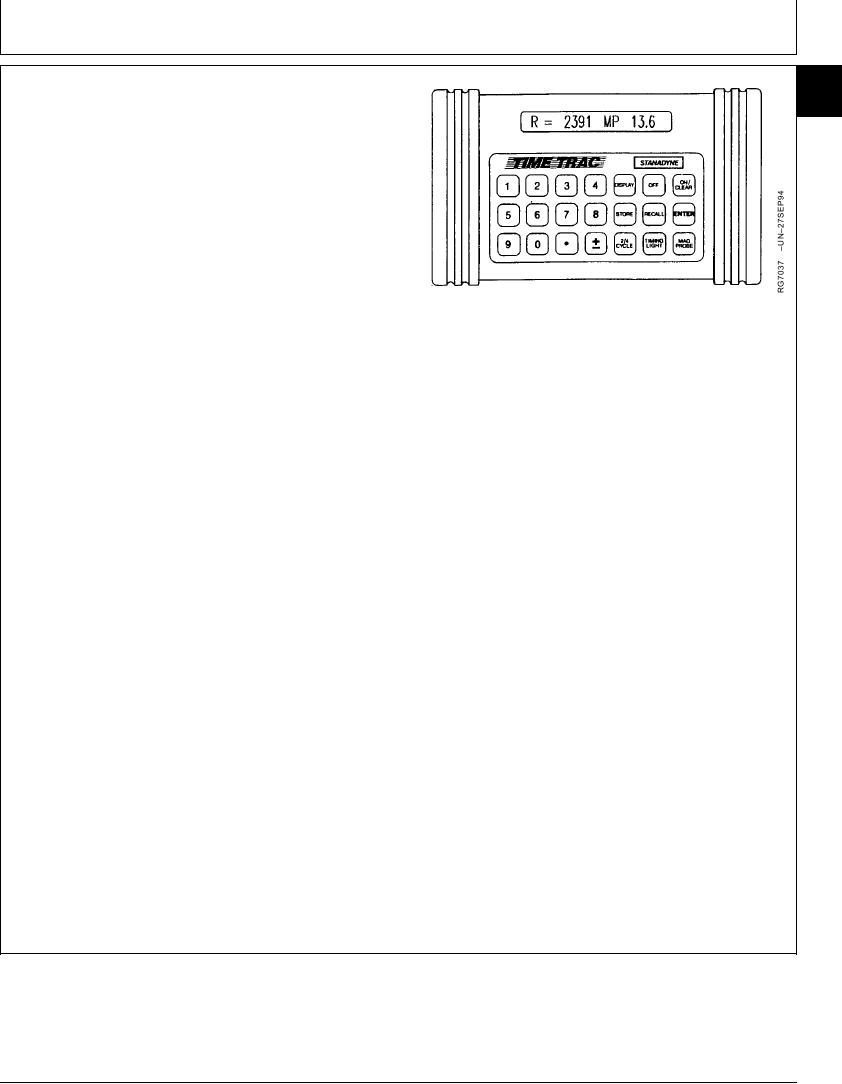

speed to rated load rpm.

8. Run engine at wide open throttle (WOT) and load

engine down gradually to rated speed rpm.

9. Record engine speed (rpm) and timing degrees.

10. Compare recorded speeds and timing degrees to

charts earlier in this group for OEM applications or

refer to machine technical manual.

IMPORTANT: Stop engine prior to making timing

adjustments. Injection pump can seize if

adjustment is made with engine

running.

11. Stop engine.

If dynamic timing reading is more than 8 degrees retarded

with pump flange and front plate timing marks at original

location as shipped from factory, this may indicate the

pump advance is not functioning. Check the following:

Change fuel filter(s).

Check transfer pump for positive fuel pressure to

injection pump.

Check camshaft movement on injection pumps with

rectangular timing window.

Check pump drive shaft-to-gear key or pin to ensure

key or pin has not sheared.

If none of the above checks are conclusive, remove

pump and have necessary repairs made at an

authorized diesel repair station.

Continued on next page

RG,115,JW7711 1924NOV978/9

13-548