TM 5-3805-280-24-2

Fuel System Operation and Tests

FUEL SHUT-OFF SOLENOID OPERATIONAL

115

51

CHECK (IN-LINE INJECTION PUMPS)

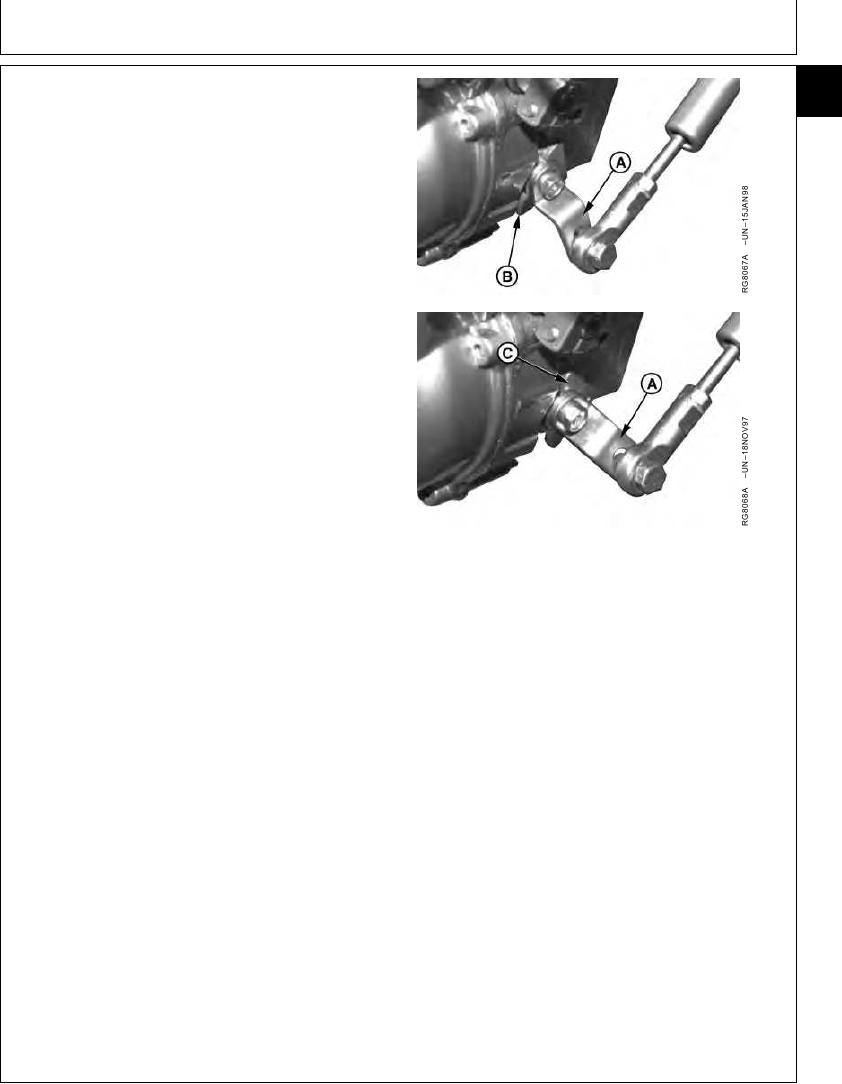

1. Observe fuel shut-off lever (A) when key switch is

turned from "OFF" to "START" (engine running at slow

idle) and then released to "ON" position.

2. Fuel shut-off lever should move from "NO FUEL"

position (B) to "RUN" position (C) when starting motor

begins to crank. The lever should remain at the "RUN"

position after key switch is released to "ON" position.

If fuel shut-off lever returns to "NO FUEL" position with

key switch at "ON" position, check for:

Loss of battery voltage to fuel shut-off winding.

Check voltage and wiring connection to solenoid.

Binding of fuel shut-off lever, solenoid rod or linkage

does not allow solenoid to lock in position. Repair or

replace linkage.

Torn or leaking rubber boot allowing dirt or moisture

to enter at spring end of solenoid rod.

Improperly adjusted fuel shut-off solenoid linkage.

See FUEL SHUT-OFF SOLENOID LINKAGE

ADJUSTMENT, later in this group.

A--Shut-Off Lever

3. Start engine and run at slow idle. Turn key switch to

B--NO FUEL Position

"OFF" position.

C--RUN Position

4. Fuel shut-off lever should move to "NO FUEL" position

and engine should stop.

If the solenoid stops just short of the "NO FUEL" position,

slight adjustment of the linkage is required. See FUEL

SHUT-OFF SOLENOID LINKAGE ADJUSTMENT, later in

this group.

If engine continues to run with key switch at "OFF"

position, unplug shut-off solenoid 3-way connector.

If solenoid moves lever to "NO FUEL" position, problem

is in the electrical circuit.

If solenoid does not shut off fuel to engine, check

linkage for binding or excessive tightness. Replacement

service kit is available with a swivel rod which is less

sensitive to misalignment and binding.

RG,115,JW7699 1924NOV971/1

13-578